12

indicating that the plasma cutter is sup-

plied with power.

4. Holding the torch away from yourself and

others in the work area, pull the torch

trigger and verify that the pressure indi-

cated on the pressure gauge is at

approximately 65 psi.

Note:

This Plasma Cutter has an internal

safety feature which prevents accidental

arcs. To light the pilot arc, press the torch

button; release it and press it again within 3

seconds The pilot arc will go out after

approximately 2-3 seconds if cutting has not

begun. To relight the pilot arc, simply repeat

the steps above. Avoid unnecessary lighting

of the pilot arc to prevent consumption of the

electrode and nozzle.

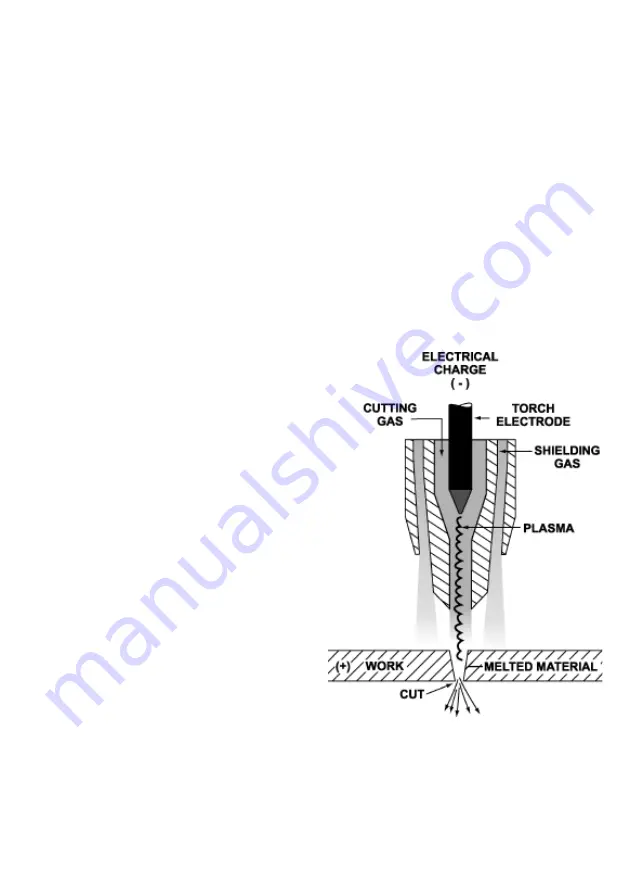

PRINCIPLES OF PLASMA CUTTING

Plasma cutting is a fast, clean and distor-

tion free means of cutting through all types of

metal from mild and stainless steels to alu-

minum, brass and copper.

The process relies upon the chemical

reaction of air when subjected to very high

temperatures. The air is ionized, leaving the

atoms positively charged. In the ionized

state, the air is electrically conductive and

called “plasma.”

A standing electric arc is created to

achieve the very high temperature required

to create plasma. By forcing the plasma

through a small nozzle, the arc is constricted

and its temperature is increased to over

36,000 degrees fahrenheit and concentrated

into a very small area.

When the plasma is directed at a conduc-

tive material (which is connected to the

ground clamp of the plasma cutter) the arc is

transferred through the plasma to the materi-

al. The high energy of the arc melts the

material. The melted metal material is simul-

taneously forced out of the cut area by the

air flow. As this glowing metal is removed

from the path of the plasma arc, the result is

a fast, clean cut.

The standing arc has to be created by

producing an ionized path in the air. This is

achieved by applying a very high voltage, at

high frequency, between the electrode and

the tip/work, causing a high frequency spark.

The main arc will ignite as soon as the tip

and nozzle are ionized.

Whether you have used a plasma cutter

before or not, it is important that you become

familiar with your new plasma cutter. We

strongly recommend that you practice with

your new plasma cutter on scrap metal trying

different base metals, base metal thicknesses,

and cutting positions. By doing this you will

gain a feel for how changes in these variables

affect the cutting process.

Of course, if you have not used a plasma

cutter before, you will need to develop prop-

er cutting skills and techniques as well.

The self-taught operator learns through a

process of trial and error. The best way to

teach yourself how to plasma cut is with

short periods of practice at regular intervals.

All practice cuts should be done on scrap

metal that can be discarded. Do not attempt

to make any cuts on valuable equipment

until you have satisfied yourself that your

practice cuts are of good appearance and

free from major faults.

LEARNING TO PLASMA CUT

Holding the Torch

The best way to hold the cutting torch is the

way that feels most comfortable to you. The

torch can be comfortably held in one hand,

or steadied using two hands. Choose the

Figure 5

. Principles of Plasma Cutting

Summary of Contents for 052249011064

Page 17: ...17 TROUBLESHOOTING...

Page 18: ...18 18 PLASMA CUTTER MODEL WE6493A WIRING DIAGRAM...

Page 19: ...19 19 PLASMA CUTTER MODEL WE6493A PARTS LIST...

Page 20: ...20 PLASMA CUTTER MODEL WE6493A PARTS DIAGRAM...

Page 21: ...21 PLASMA CUTTER MODEL WE6493A TORCH PARTS LIST...

Page 22: ...NOTES...

Page 23: ...NOTES...

Page 24: ...120V PLASMA CUTTER OPERATING MANUAL Model WE6493A WE6493A M001 1204...