-18 - FORM NO. 70202B

Clarke

®

American Sanders Operator's Manual - Sander 1600 120V

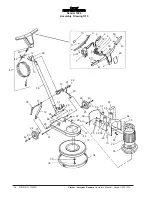

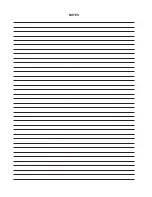

Figure 7

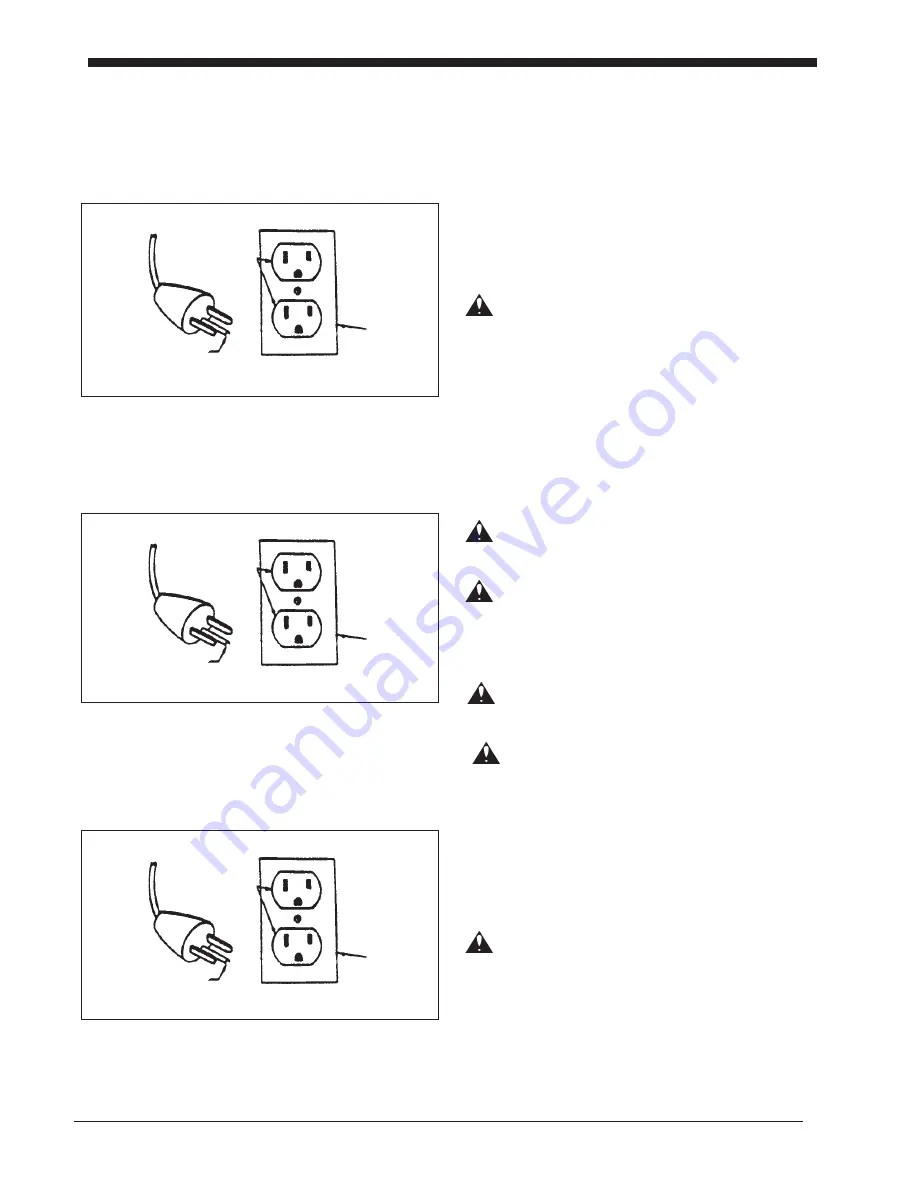

Figure 7a

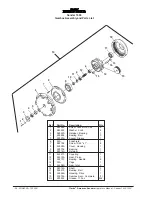

Figure 7b

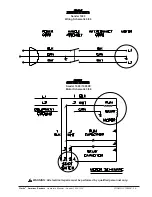

120 VOLT MACHINES

Instructions for connection to the power

supply and the electrical ground.

This product must be grounded. If it should malfunction

or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of

electrical shock. This product is equipped with a cord

having an equipment-grounding conductor and ground-

ing plug. The plug must be inserted into an appropriate

oulet that is properly installed and grounded in accor-

dance with all local codes and ordinances.

WARNING: Improper connection of the equip-

ment-grounding conductor can result in a risk of

electric shock. Check with a qualified electrician

or service person if you are in doubt as to whether

the outlet is properly grounded. Do not modify the

plug provided with the product - if it will not fit the

outlet, have a proper outlet installed by a qualified

electrician.

This product is for use on a nominal 120 volt circuit and

has a grounding attachment plug that looks like the plug

illustrated in Fig. 7. Make sure that the product is

connected to an outlet having the same configuration as

the plug. No adaptor should be used with this product.

WARNING: To prevent possible electric shock,

protect the machine from rain. Keep the machine

in a dry building.

WARNING: To prevent possible electric shock,

always use a 3-wire electrical system connected

to the electrical ground. For maximum protection

against electrical shock, use a circuit that is

protected by a ground fault circuit interrupter.

Consult your electrical contractor.

WARNING: Do not cut, remove or break the

ground pin. If the outlet does not fit the plug,

consult your electrical contractor.

WARNING: Have worn, cut or damaged

cords replaced by an authorized service person.

EXTENSION CORDS

Use only an approved extension cord with three

conductors, a plug with three terminals, and a

connector body with three holes. The machine has a

power cord with wire size 14 AWG (AWG means

American Wire Gauge).

WARNING: If you use an extension cord,

use an extension cord with minimum wire size

12 AWG. Do not use an extension cord longer

than 50 feet. Do not join two extension cords.

Grounded

Outlet

Grounding

Pin

Grounded

Outlet

Box

Toma

corriente

con polo

de tierra.

Terminal

de tierra

Tapa del

toma

corriente

con polo

de tierra.

Prise de

courant

avec mise

à la terre

Broche de mise

à la terre.

Boîte de

sortie

mise à la

terre

(United States, Mexico and Canada)

Summary of Contents for 07100A

Page 23: ...22 FORM NO 70202B Clarke American Sanders Operator s Manual Sander 1600 120V NOTES...

Page 31: ...NOTES...

Page 32: ......