7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

PREPARATION FOR USE

A. ENVIRONMENTAL

• Ensure the compressor is sited on a firm level surface.

• Ensure the environment is dry and dust free.

• Ensure there is adequate ventilation for: (a) Air intake to compressor

pump, (b) Cooling for compressor pump, (c) Engine exhaust gases.

B. ENGINE

Check oil and fuel levels and a visual check of components. Refer to engine

service manual.

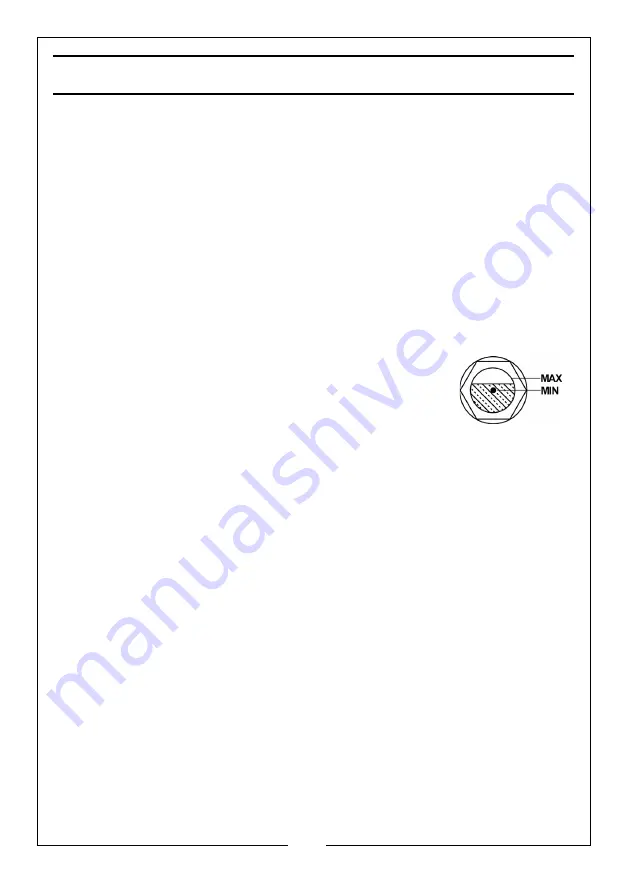

C. PUMP

• Check oil level on the sightglass - to level marked.

D. FUELLING

Fill with unleaded petrol, according to the instructions within

the engine manual.

• Ensure the fuel tap is set to the required position.

• Ensure The fuel hose and connectors are intact, in perfectly serviceable

condition and there is no leakage.

NOTE:

Always use a funnel to fill the fuel tank so as to avoid accidental

spillage of fuel. If fuel is spilled it must be removed from the unit

and surrounding area, before attempting to start the engine.

E. RECEIVER

• Drain off any condensate, by opening the drain cock (see Fig. 1).

Remember to close the drain cock when completed.

NOTE:

This should be carried out DAILY when the compressor is in

constant use.

F. AIR HOSE & AIR TOOL

• Attach the air hose to the outlet using an appropriate connector.

• Attach the air tool/spray gun to the air hose...If using snap couplings, use

a whip end, available from your Clarke dealer.

Summary of Contents for 2092500

Page 16: ......