Summary of Contents for 20CI

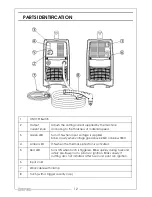

Page 1: ...OPERATION MAINTENANCE INSTRUCTIONS LS0109 PLASMA CUTTER MODEL NO 20CI PART NO 6016020 ...

Page 2: ...2 ...

Page 24: ...24 WIRING DIAGRAM ...

Page 25: ...25 DECLARATION OF CONFORMITY ...

Page 26: ...26 NOTES ...

Page 27: ...27 NOTES ...

Page 28: ......