19

MAINTENANCE

CAUTION: BEFORE PERFORMING ANY MAINTENANCE ON THE PLASMA

CUTTER LET IT COOL.

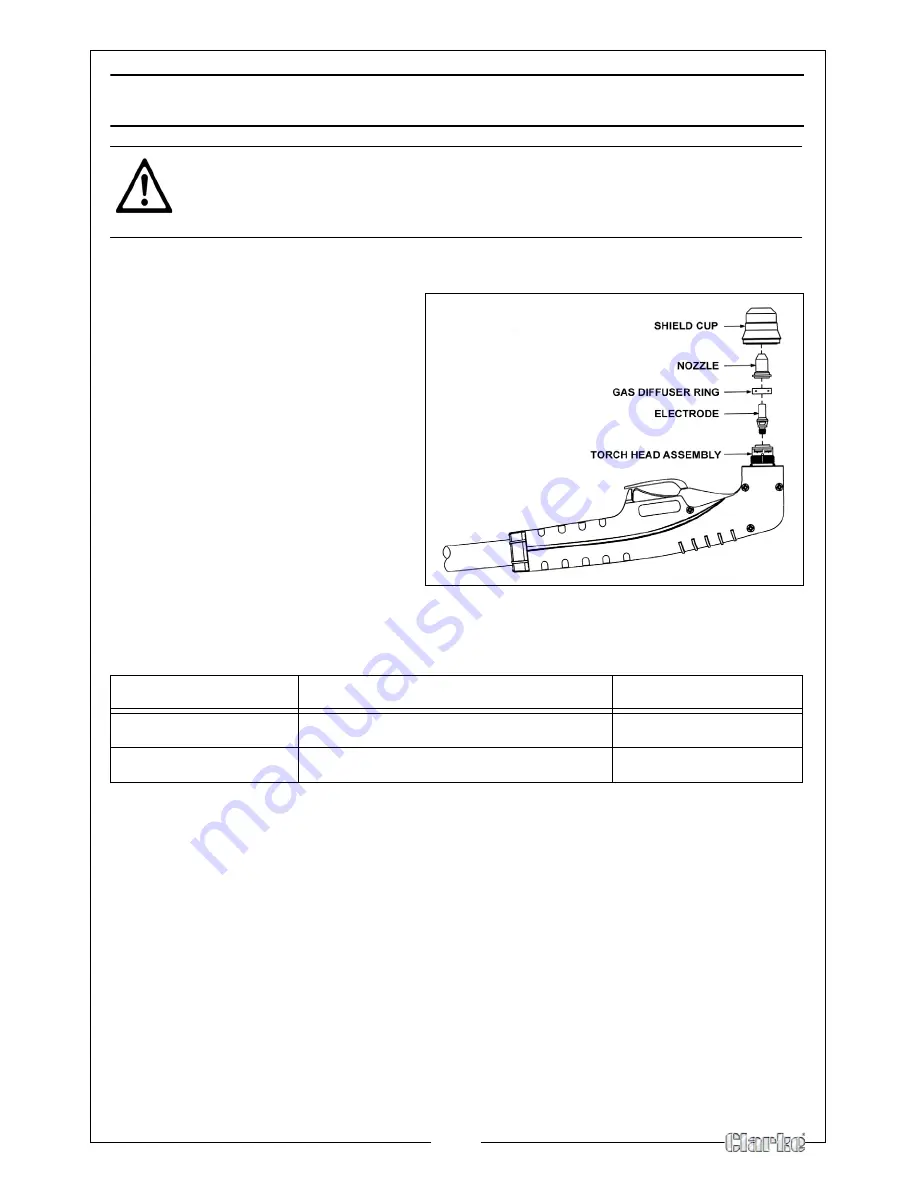

TORCH

To replace the consumables in

the torch:

1. Unscrew the shield cup from

the torch head assembly.

• Clean the shield cup

thoroughly and replace if it

is damaged (burns,

distortions or cracks).

2. Remove the nozzle, gas

diffuser ring and electrode.

• Always replace the nozzle,

gas diffuser ring and

electrode at the same time

3. Fit a new nozzle, gas diffuser ring and electrode.

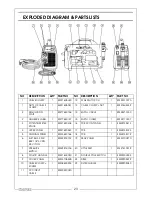

NOZZLE DIAMETER

THICKNESS OF MATERIAL BEING CUT

OUTPUT CURRENT

0.80 mm

> 5mm

20-30 Amps

0.65 mm

< 5mm

10-20 Amps

4. Replace the shield cup and ensure that it is secure.

IMPORTANT: Make sure that you do not cross tread the shield cup when you

reassemble the torch.

UNIT

• Keep the area around the machine clean and free of combustible

materials.

• Do not allow debris to collect, this could obstruct air flow to the

machine.

• Inspect the unit every 3-4 months (depending on how often the unit

is used) and use compressed air to remove any dust deposits.

Summary of Contents for 30SI

Page 1: ...OPERATION MAINTENANCE INSTRUCTIONS LS1208 PLASMA CUTTER MODEL NO 30SI PART NO 6016010...

Page 2: ...2...

Page 25: ...25 WIRING DIAGRAM...

Page 26: ...26 DECLARATION OF CONFORMITY...

Page 27: ...27 NOTES...

Page 28: ......