20

TORCH BODY, HANDLE AND CABLE

These parts need no particular maintenance with the exception of a periodic

inspection and cleaning

To keep the torch and the cable in good working order it is necessary to follow

these precautions:

• DO NOT use solvents or strong detergents when cleaning the plasma

cutter.

• If there is damage to the insulation such as breaks, cracks and burns

or even a loosening of electric conductors, the torch must not be

used.

• DO NOT touch torch and cable with warm or hot parts.

• DO NOT strain the cable.

• DO NOT move the cable on sharp edges or abrasive surfaces.

• DO NOT step on the cable.

• All repairs must be carried out buy a qualified service engineer.

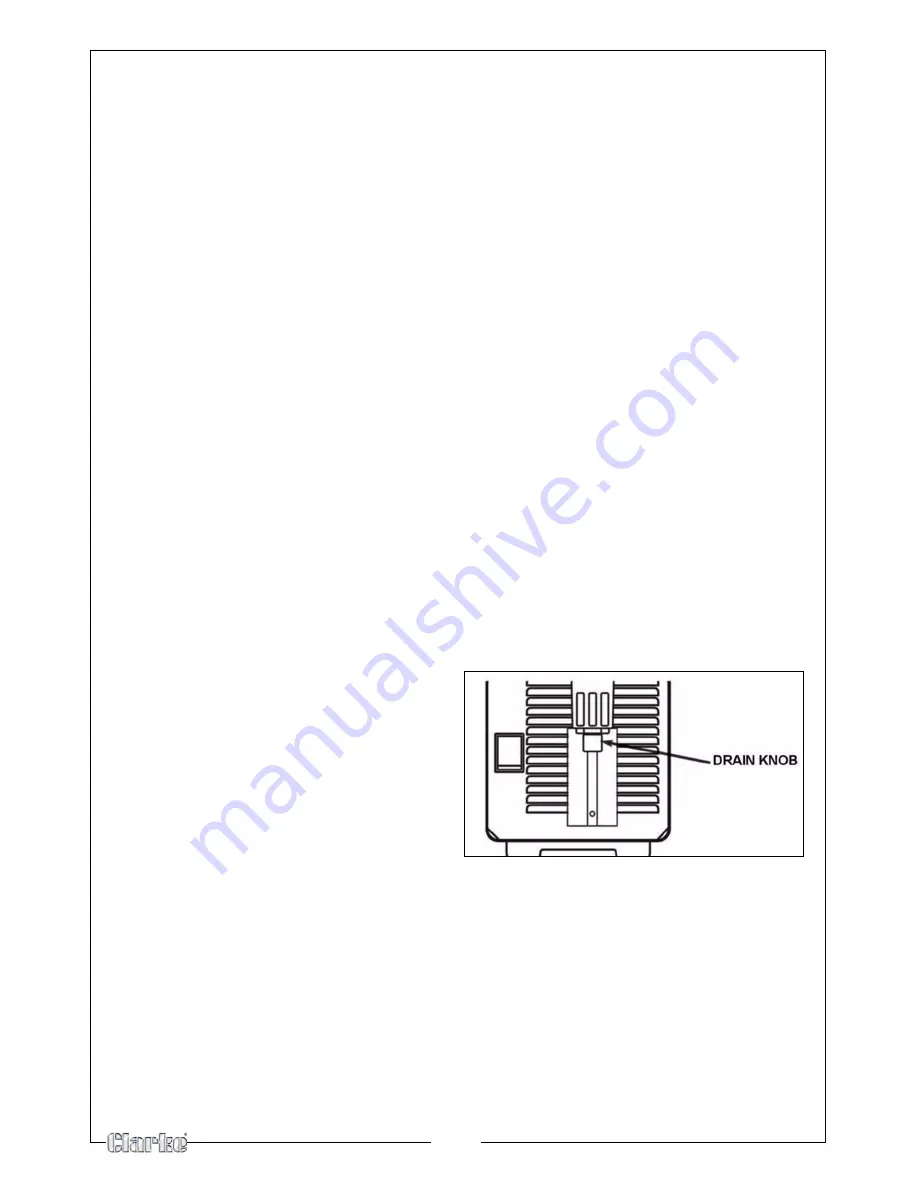

COMPRESSED AIR FILTER

The unit is equipped with a filter for the compressed air. This filter is fitted with a

knob for the manual drain of the condensation. Purge periodically to remove

the water/oil in the filter by following the instructions below.

MANUAL PURGE

• Oil in the air is a severe problem

and must be avoided.

• The unit is equipped with an air

filter which captures water and

oil vapor.

• The vapor collected can be

drained out by turning the drain

knob located on the bottom of

the air filter.

The drain knob has 3 positions: -

Open, Automatic (Open when no air pressure, closed when air pressure.) or

closed

The drain knob should be closed during cutting operations (position 2 or 3).

REPLACING THE AIR FILTER

The air filter and air filter cartridge can only be replaced by a qualified service

engineer, contact your nearest Clarke service department See page 3.

Summary of Contents for 30SI

Page 1: ...OPERATION MAINTENANCE INSTRUCTIONS LS1208 PLASMA CUTTER MODEL NO 30SI PART NO 6016010...

Page 2: ...2...

Page 25: ...25 WIRING DIAGRAM...

Page 26: ...26 DECLARATION OF CONFORMITY...

Page 27: ...27 NOTES...

Page 28: ......