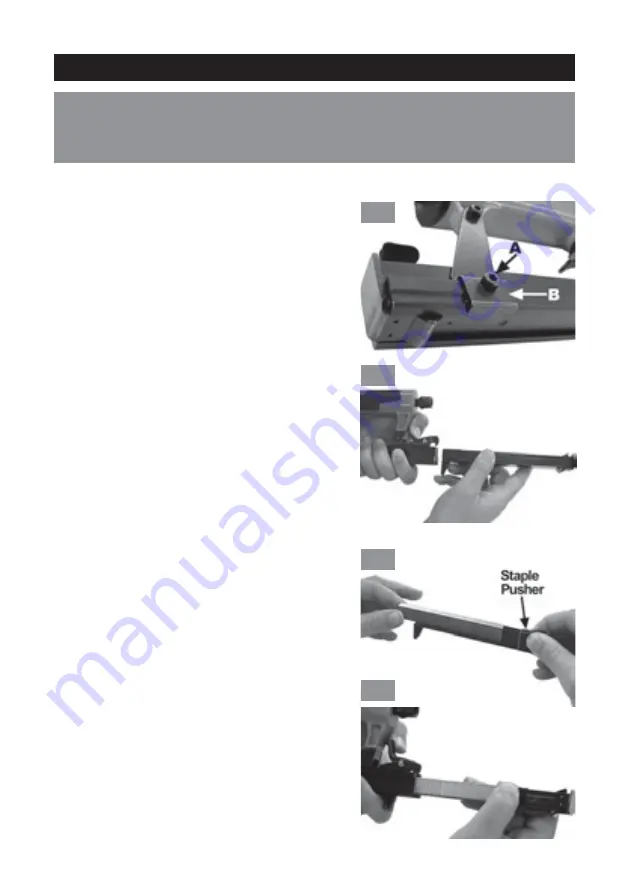

LOADING THE STAPLE GUN

WARNING!

Ensure that the power supply is off before attempting to load the gun. This

will ensure that the gun will not fire unintentionally.

1.

Using the Hex. Wrench supplied, remove

the Hex. socket head screw, ‘A’, Fig. 2,

to release the plate ‘B’.

Fi

g.5

Fi

g.4

Fi

g.3

Fi

g.2

2.

Release the Magazine by pressing down

on the magazine catch, then pull out the

magazine, as shown in Fig. 3.

3.

Pull back the staple pusher against spring

pressure, then place the staples on the

magazine ridge as shown in Fig. 4.

4.

Holding the staple pusher, feed the

magazine back into the housing as

shown in Fig. 5, Press the magazine catch

down to allow the end of the magazine

to snap home fully, then release the

catch.

5.

Replace plate ‘B’ and secure with the

hex socket head screw ‘A’, Fig.2.

The staple gun may be loaded with staples as follows:

6

Summary of Contents for 3110258

Page 9: ...PARTS DIAGRAM 9...