6

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

BEFORE USE

ASSEMBLING THE NEEDLE HOLDER

The needle scaler is packed in two halves.

• The main body and hammer assembly

• The needles with needle holder, needle tube and spring

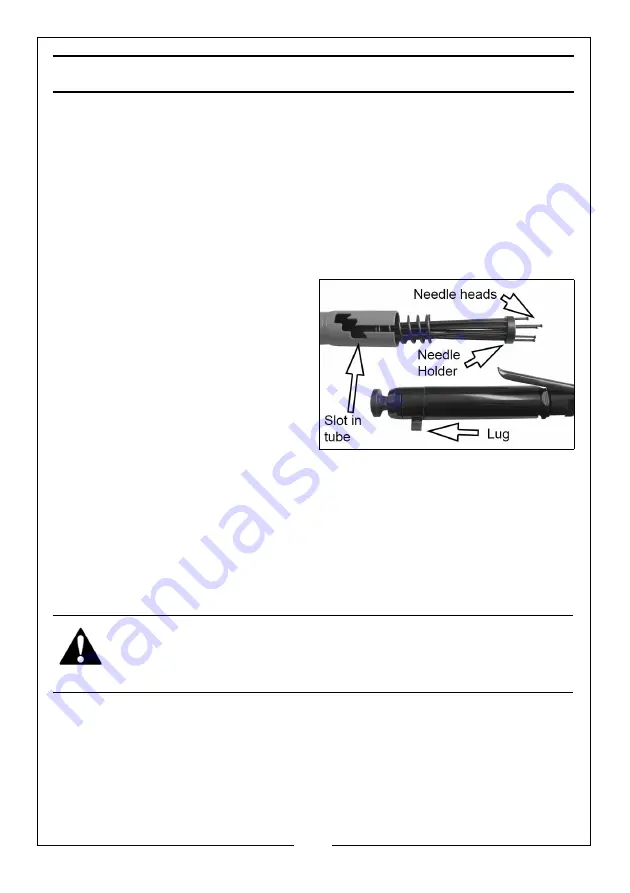

1. Insert the needles, needle holder and spring into the needle tube, Ensure

the needle holder is the correct way round, so that the heads of the

needles sit snugly in the recesses in the holder.

2. Push the needle tube, complete

with needles, needle holder and

spring, on to the main body so that

the retaining lug in the body enters

the slot in the side of the tube.

Continue to push against spring

pressure until the body can be

twisted, and thereby locked, into

one of three positions.

The first position, achieved by turning

the body and the retaining lug

anticlockwise, creates the greatest needle force, the second position,

achieved by pushing harder against spring pressure and turning the body

clockwise, creates a slightly lesser force, and the third position, achieved in a

similar manner, creates even less.

3. Select a position depending upon your work requirements, dictated by the

finish required and the type of material being worked on.

CONNECTING THE AIR SUPPLY

1. Remove the protective plug from the air inlet port and connect a suitable

hose.

2. A gauze filter is fitted within the air inlet adapter. Ensure this filter is always in

place and clean. The airline is connected to the adapter, preferably via a

quick release coupling (not supplied).

3. Connect the other end of the hose to the compressor.

WARNING: COMPRESSED AIR CAN BE DANGEROUS. ENSURE THAT YOU

ARE FAMILIAR WITH ALL PRECAUTIONS RELATING TO THE USE OF AIR

COMPRESSORS AND A COMPRESSED AIR SUPPLY.

Summary of Contents for 3120187

Page 12: ......