15

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

5. Slide the belt off and replace with a new one, ensuring it lies centrally on

the top and bottom rollers

6. Retighten the top roller securing knob till it becomes firm but NOT too tight.

7. Tighten the belt tension adjuster nut until it also becomes firm. DO NOT

overtighten. The belt should now be fairly taught and positioned centrally

on the rollers.

IMPORTANT: The belt needs just enough tension to ensure that it does not

slip on the rollers whilst under load, however too much tension will shorten

the working life of the belt and the machine.

8. Replace the sanding belt cover, then adjust and tighten the work rest.

9. Rotate the belt by hand whilst

screwing the Tracking Adjustment

screw in or out to ensure the belt

runs centrally on the rollers. Turn

the screw anticlockwise to move

the belt outwards (towards the

outer cover), or clockwise to

move inwards.

10. When satisfied, plug the machine

into the power supply and switch

ON. Make fine adjustments with

the Tracking Adjustment screw if necessary.

CLEANING & STORAGE

Clean the exterior of the machine if required using a mild detergent or mild

solvent. Never immerse the machine in water. To reduce any fire hazard, keep

any cooling vents clear. If not bolted to a workbench, store the grinder in a

clean, dry location, out of reach of children.

ACCESSORIES

Description

Part No

Grinding Wheel - Fine

6501135

Grinding Wheel - Medium

6501089

Grinding Wheel - Course

6501088

Grinding Wheel Dressing Tool - GWD1

6501120

Sanding Belts - Fine (pack of 5)

6502115

Sanding Belts - Medium (pack of 5)

6502120

Sanding Belts - Course (pack of 5)

6502125

Bench Grinder Stand

6501140

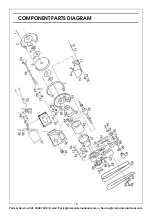

Summary of Contents for 6500032

Page 20: ......