4

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

3. NEVER abuse the mains cable. Never yank the cable to disconnect it from

the socket. Keep the cable away from sharp edges/hot surfaces.

4. NEVER carry out any alterations or modifications to this product.

5. NEVER wipe the machine clean with solvents. Wipe plastic parts with a soft

cloth, slightly dampened with soapy water.

6. NEVER attempt any repairs yourself. If you have a problem with this product

contact your local CLARKE dealer.

7. Do not use the tool for any purpose than that described in this manual.

8. Always maintain the tool with care. Keep it clean for the best and safest

performance.

9. Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the

rate which it was designed.

10. Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and

must be repaired.

11. Store idle tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of untrained users.

12. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power

tools operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

13. Use the power tool and accessories in accordance with these instructions

and in the manner intended for the particular type of power tool, taking

into account the working conditions and the work to be performed. Use of

the power tool for operations different from intended could result in a

hazardous situation.

ELECTRICAL SAFETY

1. Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use adapter plugs with earthed (grounded) power tools. Correct

plugs and matching outlets will reduce the risk of electric shock.

2. Do not abuse the cable. Never use it for carrying, pulling or unplugging the

power tool. Keep the cable away from heat, oil, sharp edges or moving

parts. Damaged or entangled cables increase the risk of electric shock.

3. Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock. If operating the power

tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply.

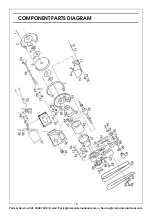

Summary of Contents for 6500032

Page 20: ......