2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

INTRODUCTION

Thank you for purchasing this CLARKE buffer/polisher. Before attempting to use

this product, please read this manual thoroughly and follow the instructions

carefully. In doing so you will ensure the safety of yourself and that of others

around you, and you can look forward to your purchase giving you long and

satisfactory service.

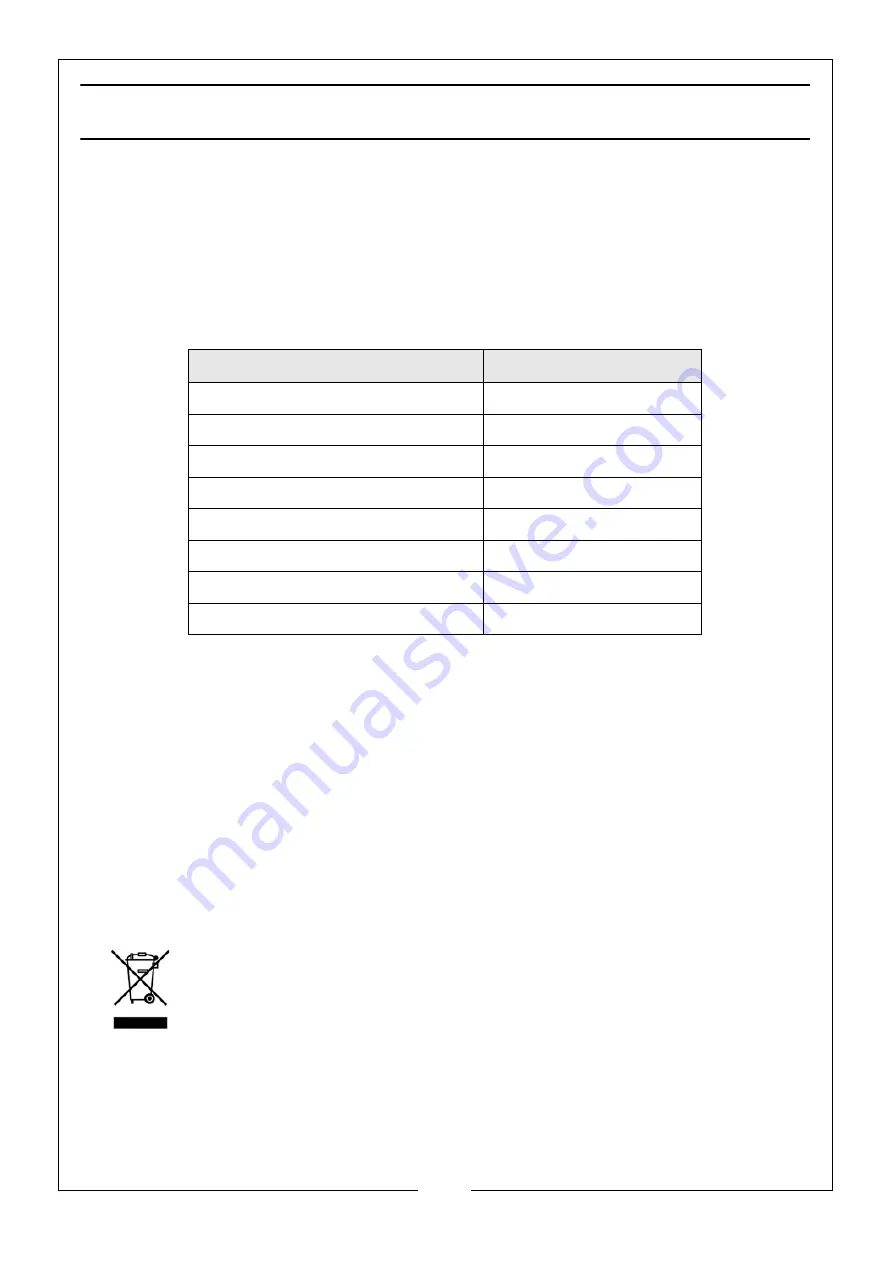

SPECIFICATIONS

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended. Faulty goods should be returned to their place of purchase, no

product can be returned to us without prior permission. This guarantee does

not effect your statutory rights.

ENVIRONMENTAL PROTECTION

Through purchase of this product, the customer is taking on the

obligation to deal with the WEEE in accordance with the WEEE

regulations in relation to the treatment, recycling & recovery and

environmentally sound disposal of the WEEE.

In effect, this means that this product must not be disposed of with general

household waste but according to the laws governing Waste Electrical and

Electronic Equipment (WEEE) at a recognised disposal facility.

CBB150

Motor Power

250W

Fuse Rating

5 Amp

Rated Voltage / Frequency

230V / 50Hz

Shaft Diameter

12.7 mm

No Load Speed

2850 rpm

Wheel Diameter

150 mm

Dimensions

210 x 480 x 220 mm

Weight

8.9 kg

Summary of Contents for 6500485

Page 12: ......