9

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

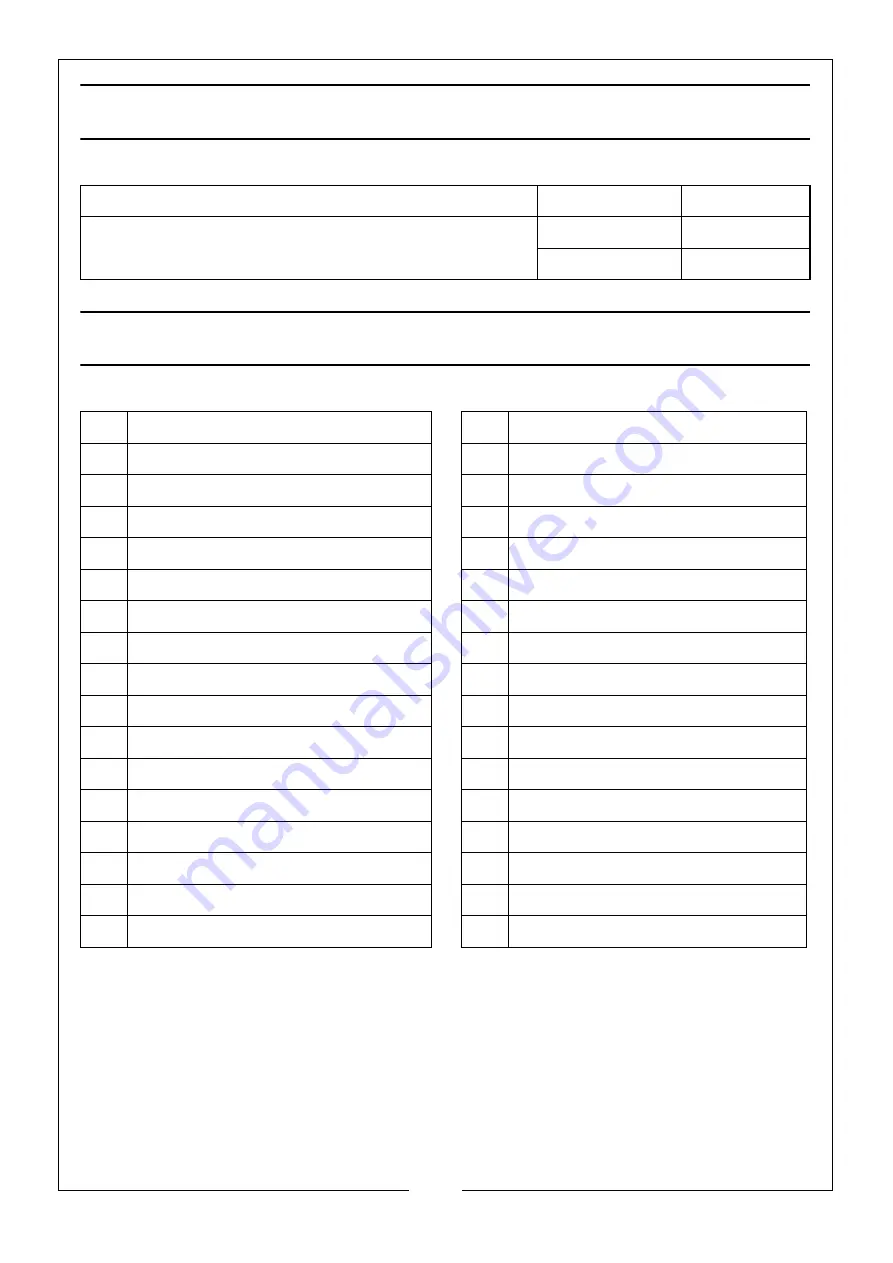

REPLACEMENT POLISHING MOPS

COMPONENT PARTS

TYPE

PART No

150 mm REPLACEMENT POLISHING MOPS

OPEN

6500486

STITCHED

6500487

1

Nut M12 (Left-hand tread)

18

Power cable gland

2

Retaining disc

19

Switch

3

Less thread buffing wheel

20

Philips screw M5x8

4

Spacer bush

21

Switch board

5

Nut M5

22

Base

6

End cap

23

Nut M8

7

Corrugated retainer

24

Capacitor bracket

8

Bearing 6202

25

Capacitor

9

Power cable & plug

26

Philips screw & washer M6x20

10

Rubber sleeve

27

Base plate

11

Multi-wire cloth buffing wheel

28

Rubber foot

12

Rotor

29

Philips screw & washer M4x12

13

Nut M12

30

Cable clip baseplate

14

Stator

31

Philips screw M6 x 16

15

Philips screw & washer M5x200

32

Strain relief baseplate

16

Ext tooth lock washer

33

Strain relief plate

17

Philips screw & washer M4x8

Summary of Contents for 6500485

Page 12: ......