19

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

OPERATING - BRAKE

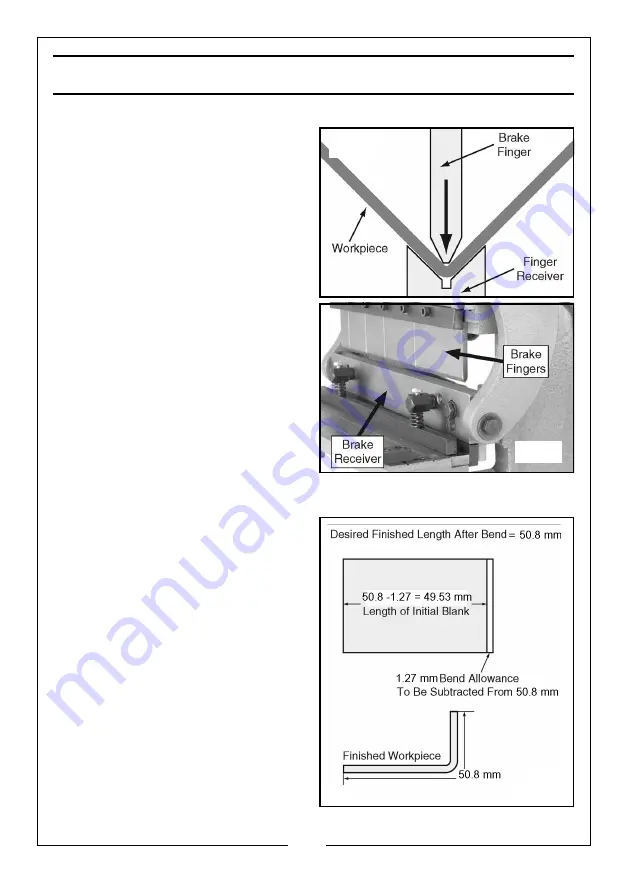

BRAKE OVERVIEW

The brake of the SBR305 is used to

make bends of 0°-90° in sheet metal

up to 1 mm in thickness and 305 mm

in width. When you use the hand

crank, the brake fingers force the

workpiece into the groove of the

finger receiver to make the desired

bend (see Figures 29-30).

BEND ALLOWANCE

When metal is bent, the outside

overall dimension increases from its

original length-this amount is called

the bend allowance. A typical bend

allowance for a 90° bend in a 1 mm

mild steel workpiece is approximately

1.27 mm. That means you need to

start with a workpiece that is

approximately 1.27 mm shorter than

the desired outside length of the

finished workpiece, as illustrated in the example of Figure 31.

Calculating the bend allowance for

your operation requires many

variables, such as metal thickness,

type of material, radius of the bend,

etc. Detailed information for

calculating the bend allowance can

be found in metalworking handbooks

and on the internet.

An easy way to find the correct

dimension of your initial blank is to

measure a piece of scrap of the

same material as the workpiece,

make the bend, then measure the

piece again. The difference between

the two measurements is the bend

allowance, which you subtract from

the dimension of the workpiece

blank before the bend.

Fig. 29

Fig. 30

Fig. 31

Summary of Contents for 6560000

Page 36: ......