29

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

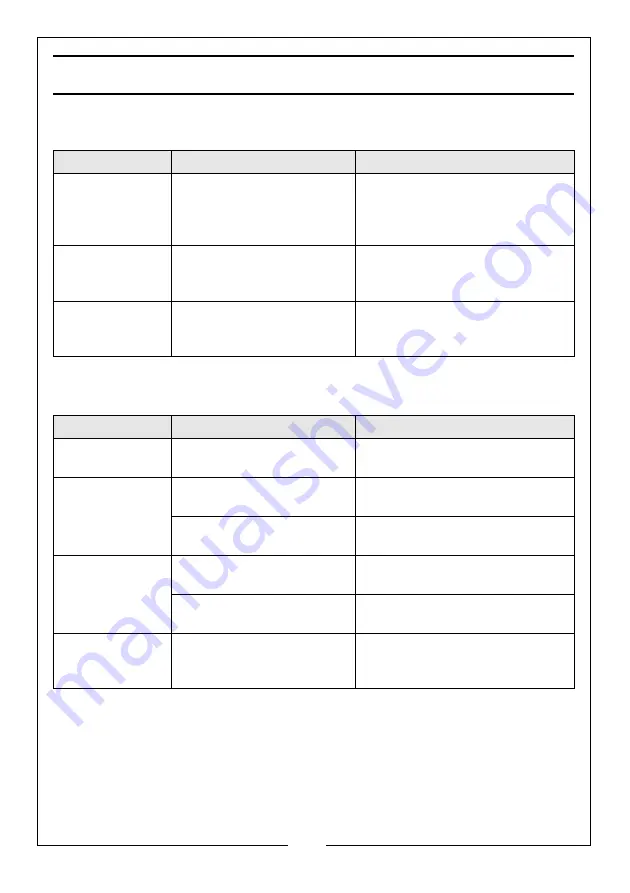

TROUBLESHOOTING

Slip Roll Operation

Brake Operation

PROBLEM

CAUSE

SOLUTION

Slip roll creates

cones when trying

to make a

cylinder.

Top and rear rollers not

parallel.

Use the diameter adjustment knobs

to make the rollers parallel.

Creases or

wrinkles in the

workpiece.

Excessive pressure applied

when rolling.

Reduce the radius and perform the

bend in several light passes.

Workpiece is

pitted or

scratched.

Workpiece or rollers are dirty

or damaged.

Thoroughly clean the workpiece

and rollers. Polish out any nicks/

burrs in the rollers, or replace them.

PROBLEM

CAUSE

SOLUTION

Heavy resistance

during bending.

Machine capacities are

exceeded.

Operate within the listed capacities

of the machine.

Bend radius is not

consistent across

workpiece.

Machine capacities are

exceeded.

Operate within the listed capacities

of the machine.

Fingers and receiver not

aligned.

Properly align the fingers and

receiver

Tips of brake

fingers are

chipping or rolling.

Fingers and receiver not

aligned.

Properly align the fingers and

receiver

Workpiece is too thick.

Operate within the listed capacities

of the machine.

Workpiece has

scoring marks.

Fingers or receiver scratched Polish out scratches, and apply

tape at the bend locations for

further protection

Summary of Contents for 6560000

Page 36: ......