10

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

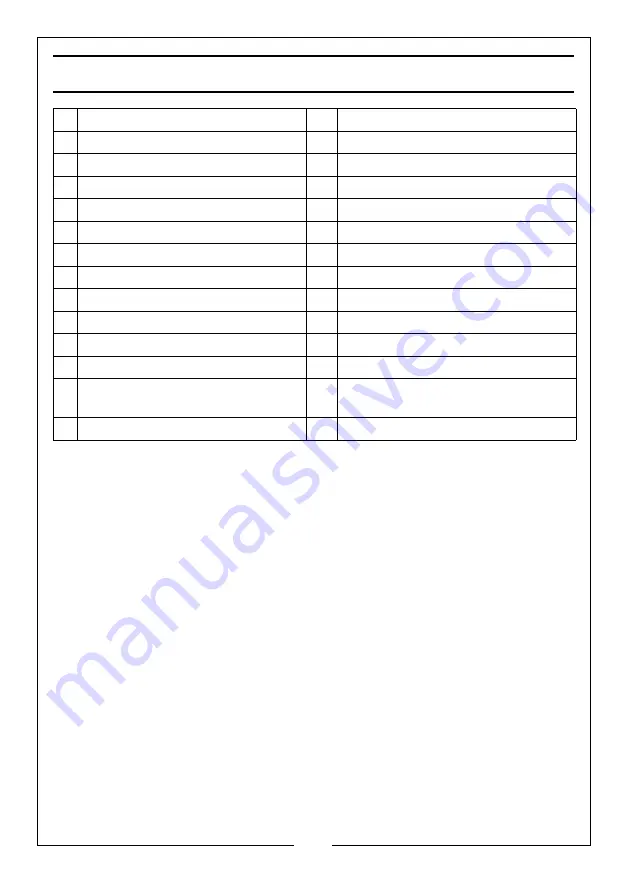

PARTS IDENTIFICATION

THE HEADSTOCK

The motor provides a direct drive to the Spindle via an internal tooth type belt.

Spindle speed is variable and is regulated by the Speed Control Knob (23),

located on the main control panel.

The spindle is provided with an internal No.3 Morse taper to accommodate a

centre for use with a face plate or turning clamp, (See ‘Accessories’ on page

30).

The Chuck Guard (3), is an essential component and is mounted on a pin

which is secured to the headstock by two screws. This should always be in

place when using a chuck.

The 3-Jaw, Self Centering Chuck (4) is mounted on the Spindle Flange (2). To

remove the chuck, simply remove the three securing nuts to the rear of the

flange allowing it to be pulled free together with the three mounting studs.

Three external jaws are also supplied which extend the capacity of the chuck.

Their uses and method of assembly is described under ‘Accessories’ on page

30.

The spindle has 6 holes drilled in its flange to accommodate a range of fixtures

such as a Face Plate, 4-Jaw chuck etc, (See ‘Accessories’ on page 30).

1

Headstock

15

Automatic Feed Lever

2

Spindle Flange

16

Cross-Slide Feed Handle

3

Chuck Guard

17

Apron

4

3-Jaw Chuck

18

Manual (Saddle) Feed Handle

5

Tool Post

19

Leadscrew

6

Cross-Slide

20

Motor Brush Cap

7

Compound Slide

21

Thread Dial Indicator Table

8

Tailstock Centre

22

Running Gear Cover

9

Tailstock

23

Variable Speed Control Knob

10 Tailstock Securing Nut

24

Forward/Off/Reverse Switch

11 Bed

25

Emergency Stop Switch

12 R.H. Leadscrew Bearing

26

High/Low Speed Range Lever

13 Compound Slide Feed Handle

27

Leadscrew Fwd/Neutral/Reverse

Lever

14 Thread Dial Indicator

28

Overload indicator

Summary of Contents for 7610700

Page 40: ......