10

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

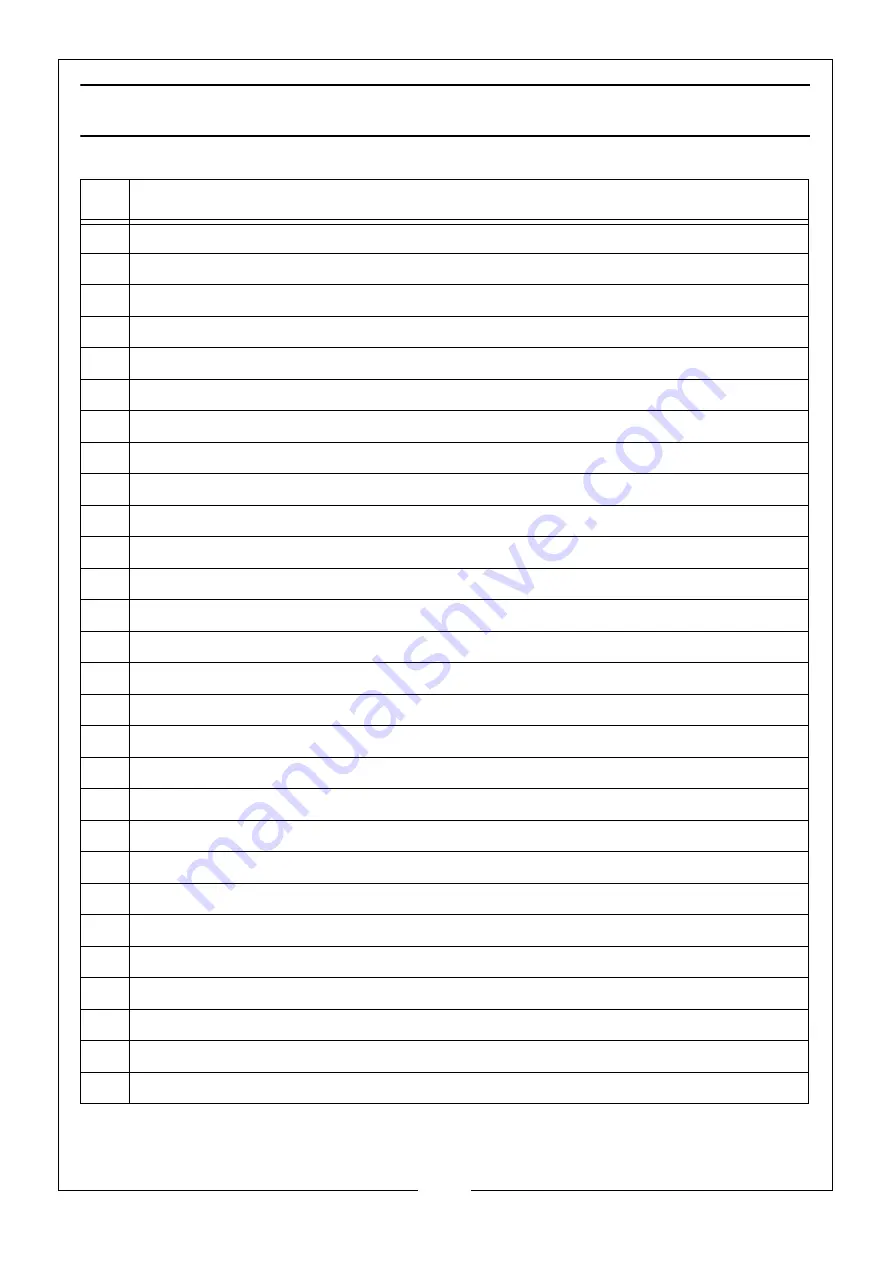

PARTS LIST

N

O

D

ESCRIPTION

1

Top cup

2

O-ring

3

Rectangular ring

4

Reservoir

5

Oil plug

6

T-ring

7

Release valve assembly

8

Ball 6mm

9

Plastic plug

10

Adjusting screw assembly

11

Spring

12

Spring holder

13

Steel ball 3mm

14

Base parts

15

Oil filter pipe

16

Cylinder ring

17

Cylinder

18

O-Ring

19

Bowl washer

20

Piston rod assembly

21

Handle assembly and Hexagon bolts

22

Cutter pin

23

Handle socket assembly

24

Pin

25

Pump plunger assembly

26

Pump

27

Washer

28

Seal kit

Summary of Contents for 7620052

Page 12: ......