5

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

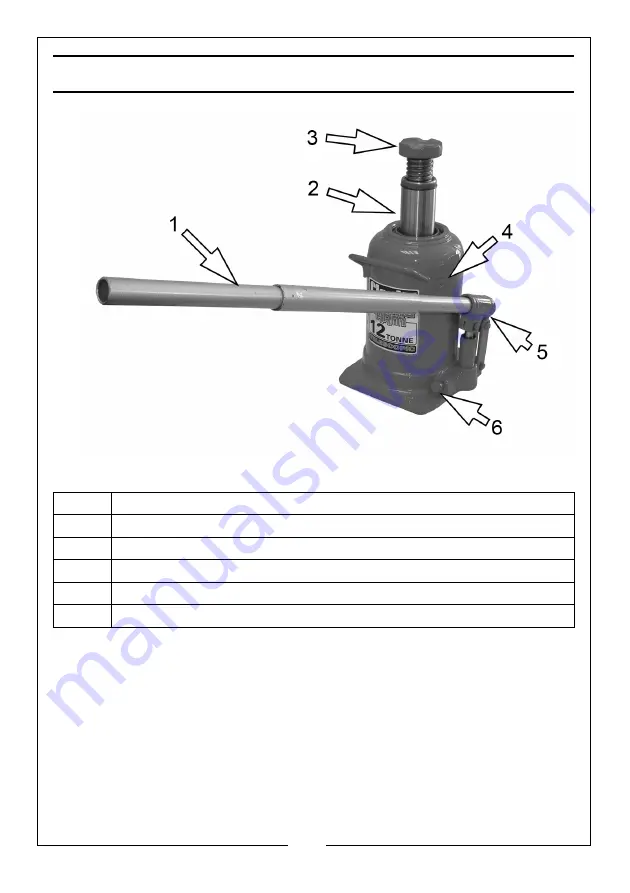

PRODUCT FEATURES

(CTBJ12 shown)

UNPACKING

During transit or storage, it is possible that an air pocket may have developed

within the hydraulic ram, and the ram action may therefore appear to be

‘spongy’. In this case the jack may require purging as described on page 7.

If the column does not reach its full height, the ram oil level may require

topping up, as described in the Maintenance section.

1

3 x Handle Tubes

2

Ram

3

Screw Extension

4

Oil Filler Plug

5

Actuating Lever

6

Release Valve

Summary of Contents for 7621037

Page 12: ......