9

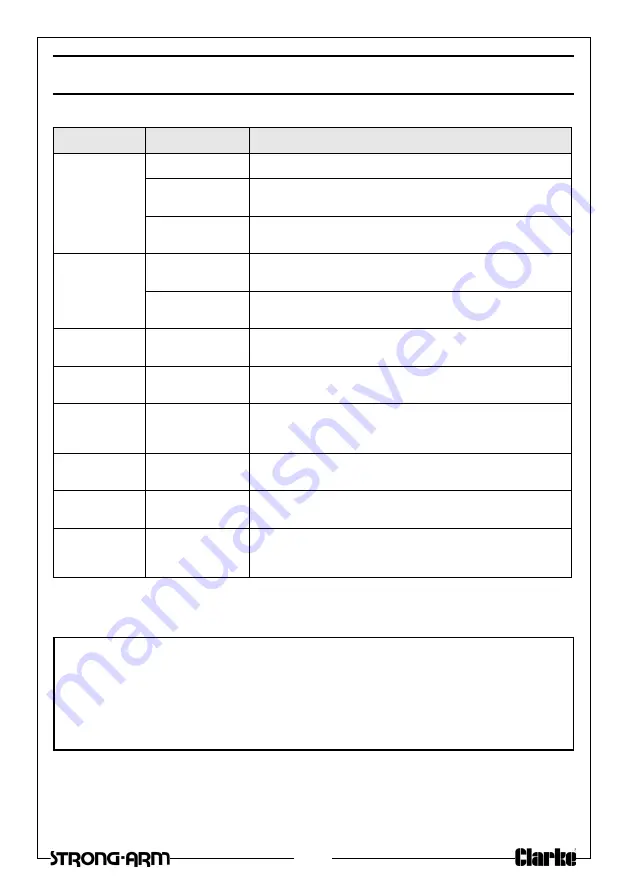

TROUBLESHOOTING

PROBLEM

CAUSE

SOLUTION

Jack will not lift

the rated load

Low Oil Level

See “Changing the oil” on page 8.

Release valve not

closed

Turn the release knob fully clockwise

Air in the hydraulic

system

Bleed the system See page 6

Jack lower

when under

load

Release valve not

closed

Turn the release knob fully clockwise

Air in the hydraulic

system

Bleed the system See page 6

Pump feels

Spongy

Low Oil Level

See “Changing the oil” on page 8.

Air in the hydraulic

system

Bleed the system See page 6

Handle raises or

flies back under

load

Air in the hydraulic

system

Bleed the system See page 6

Jack will not lift

full height

Low Oil Level

See “Changing the oil” on page 8.

Air in the hydraulic

system

Bleed the system See page 6

Jack will not

lower

completely

Return spring may

be faulty

See your Clarke Dealer

If any of these remedies fail to restore your jack, consult your Clarke dealer

For Spare Parts and Servicing, please contact your nearest dealer, or

CLARKE International, on one of the following numbers.

PARTS & SERVICE TEL: 020 8988 7400

PARTS & SERVICE FAX: 020 8558 3622

Summary of Contents for 7621045

Page 11: ...11 DECLARATION OF CONFORMITY...

Page 12: ......