6

CHECKING /MAINTAINING THE OIL LEVEL

If the jack has been stored for long periods, check for oil leaks before use. If

necessary, check the oil level as follows:

1. Ensure the jack is fully lowered by turning the control valve anticlockwise.

2. Remove the cover plate and the oil filler plug.

• The oil should be almost level with the bottom of the oil filler hole.

• il can be topped up using Clarke Hydraulic Oil (p/no 3050830 for 1

litre).

3. Purge any air from the system and replace the oil filler plug.

4. Dispose of any old/spilled oil appropriately and wipe up any spillage.

GENERAL CARE

1. Periodically lubricate the hinges, front wheels & rear castors with light oil.

Should the arm become stiff, apply a shot of grease to the grease nipple

on the top of the lifting arm as shown above.

2. Store in a dry location.

3. In the event of damage or broken components, replacements are

available from Clarke Parts & Service.

STORAGE

1. Store in a dry place with the ram fully lowered. If stored for long periods,

inspect at least once a year, clean and re-oil. For servicing, contact your

CLARKE dealer, or CLARKE International Service Department.

ENVIRONMENTAL PROTECTION

One of the most damaging sources of environmental pollution is oil products.

Never throw away used hydraulic oil with domestic refuse or flush it down a

sink or drain. Collect any hydraulic oil in a leak proof container and take it to

your local waste disposal site.

If disposing of this product or any damaged components, do not dispose of

with general waste. This product contains valuable raw materials and should

be taken to your local civic amenity site for recycling of metal products.

Summary of Contents for 7621820

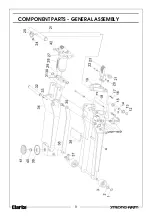

Page 8: ...8 COMPONENT PARTS GENERAL ASSEMBLY...

Page 11: ...11 COMPONENT PARTS HYDRAULIC PARTS...

Page 12: ......