6

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

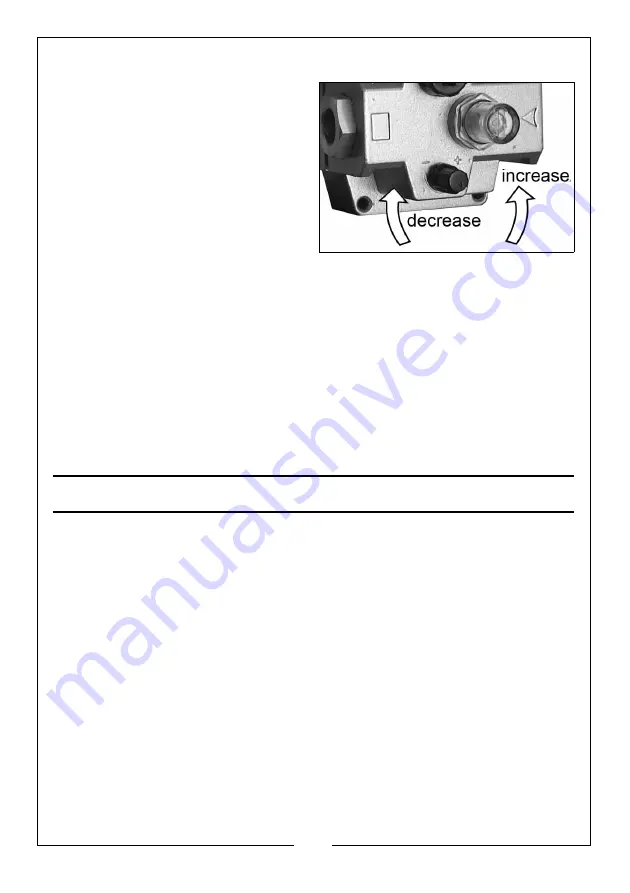

SETTING THE OIL FLOW

1. Adjust the oil delivery rate as

required, by twisting the regulator

knob in the direction shown by the

+/- symbols.

• + and - are marked on the

casting.

2. Adjust the drip rate only when

there is a constant rate of air flow

through the lubricator. Monitor the

drip rate through the sight-glass.

3. Monitor the air tool being lubricated for a few days following the drip rate

adjustment and see how well the device works, then determine whether

the drip rate at the lubricator should be adjusted for more or less oil.

Typically, the lubricator should be adjusted to approx 2 drops per minute.

• If the air tool is excessively lubricated, the reservoir will quickly

become depleted and oil mist may be noticed being expelled from

the air tool exhaust port.

• Never use lubricated compressed air when using a paint spray gun,

since oil mixed with paint will spoil the finish of the work being

sprayed.

CARE AND MAINTENANCE

With prolonged use the lubricator may become foul and require cleaning out

before further use. It should be removed and cleaned as follows:

1. Shut off the air compressor and vent any remaining air from the airline.

2. Remove the bowl housing by releasing the spring catch, pushing into the

body and twisting the bowl housing free. The oil pick-up and sight-glass

parts can then be removed for cleaning.

3. Gently clean the internal components and body using dishwashing liquid

and allow to dry.

4. Reassemble, taking care not to overtighten plastic items.

IMPORTANT: Over tightening will permanently damage the sealing o-rings.

Your lubricator has been designed to give long and trouble free service. If,

however, having followed the instructions in this booklet carefully, you

encounter problems, take the unit to your local CLARKE dealer.

Summary of Contents for Air CAT162

Page 8: ......