8

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

BEFORE USE

NOTE:

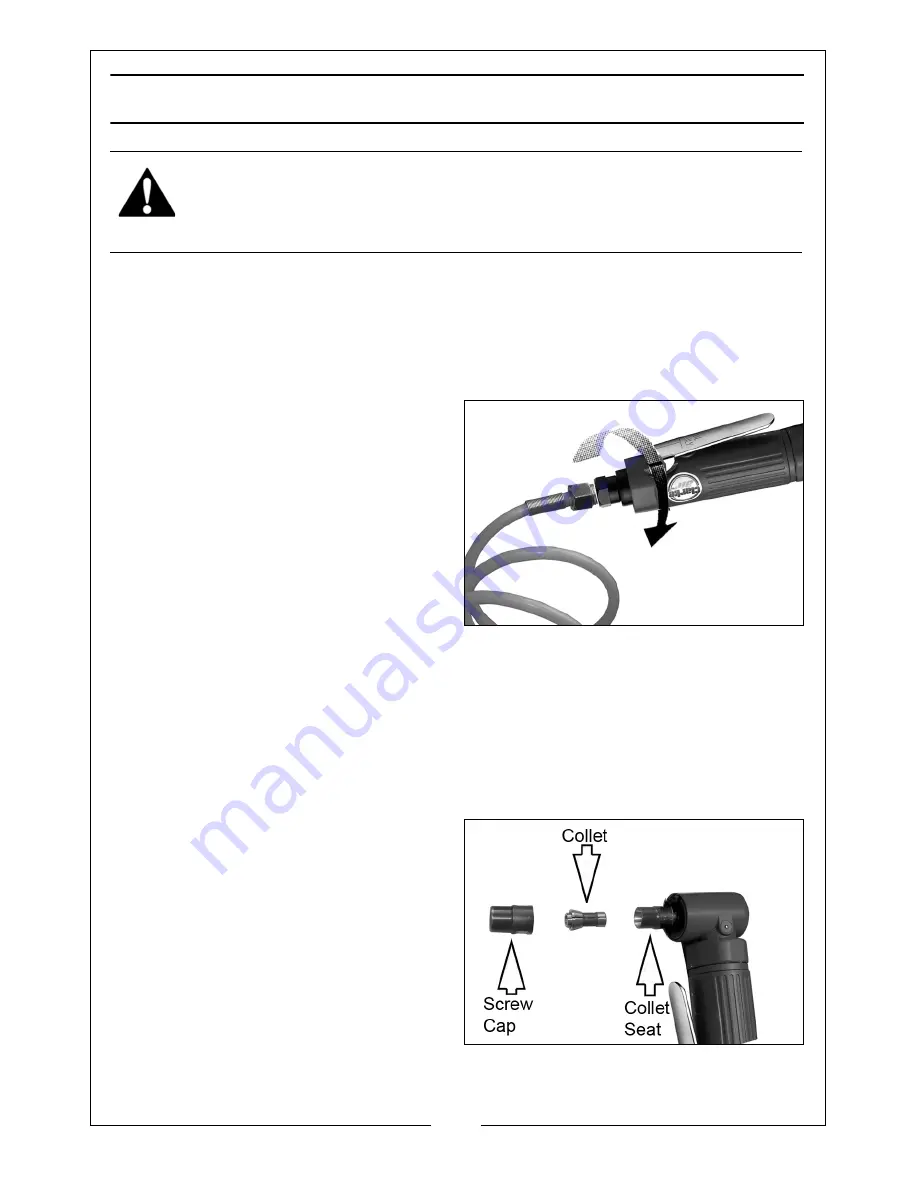

Ensure the compressor is turned off.

1. Remove the blanking plug from the inlet connection of the tool.

2. If required, connect an in-line mini oiler to the tool.

• A mini oiler helps to prolong the life of the air tool.

3. If a mini-oiler is not being used, run

a few drops of oil through the tool

before use. It can be entered

through the air inlet or via the hose

at the nearest connection to the

air supply.

4. Connect a suitable hose to the air

inlet as shown.

5. Connect the other end of the hose

to the compressor.

Your air tool is now ready for use.

You can fit a whip hose with a quick fit coupling if required (available from

your Clarke dealer).

INSTALLING THE COLLET TO THE DIE GRINDER

1. Select the grinding stone you require.

2. Two collets of different sizes are

provided. Select whichever fits

the shank of the stone you have

chosen.

• The larger collet is probably

already installed in the grinder.

3. If the other collet is to be used,

undo the screw cap completely

and pull out the collet from the

collet seat. Replace it with the

new collet and screw the cap loosely back on.

WARNING: COMPRESSED AIR CAN BE DANGEROUS. ENSURE THAT YOU

ARE FAMILIAR WITH ALL PRECAUTIONS RELATING TO THE USE OF AIR

COMPRESSORS AND COMPRESSED AIR SUPPLIES.