10

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

• Avoid overloading the polisher. If it becomes hot during use, rest for

a few minutes while it cools down.

DISCONNECTING THE AIR SUPPLY

1. DO NOT disconnect the air supply hose until the compressor has been shut

down and the compressed air released.

2. Refer to the compressor instruction manual for the procedure to shut down

and release the compressed air.

3. Once the pressure has been released, disconnect the air supply hose from

the tool.

MAINTENANCE

DAILY

1. Before use, drain water from the air tank, air line and compressor.

2. Pour a few drops of CLARKE airline oil into the air inlet. This should be carried

out regardless of whether or not an in-line mini oiler is used. If an in-line mini

oiler is not used, this procedure should be repeated after every two to

three hours of use.

CLEANING

1. Wash the mop after each use by

hand and use mild soap with

water. Hang it up to dry.

• Store flat and allow it to regain

shape.

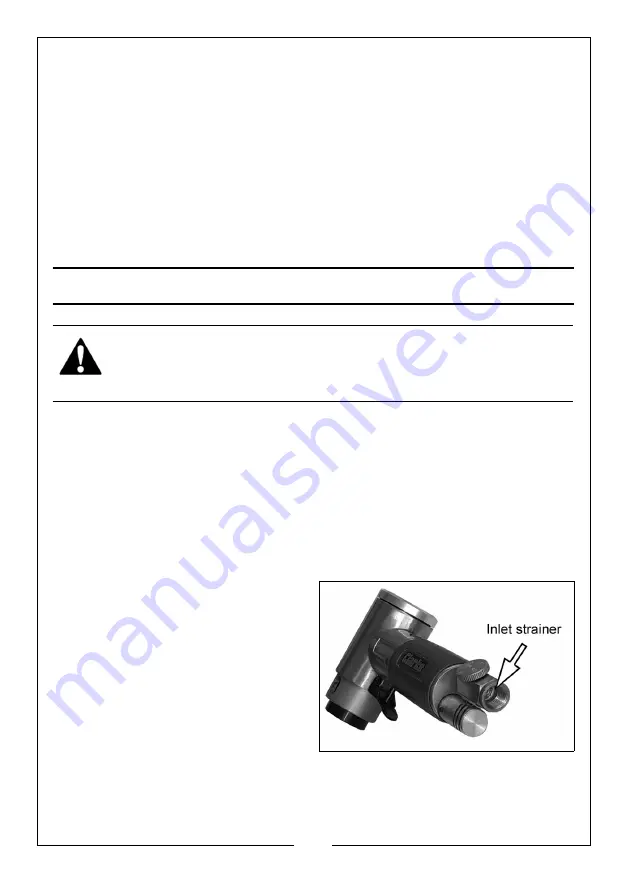

2. Check the air inlet strainer for

blockage and clean if necessary.

3. Keep the body of the tool clean

and free from debris.

4. Grit or gum deposits inside the tool may also reduce its efficiency. This

condition can be corrected by cleaning out the air strainer and flushing

out the tool with gum solvent or oil, or failing this, the motor may require

dismantling. This is better left to your CLARKE dealer.

WARNING: MAKE SURE THAT THE AIR TOOL IS DISCONNECTED FROM THE

AIR SUPPLY BEFORE STARTING ANY CLEANING OR MAINTENANCE

PROCEDURES.

Summary of Contents for CAT220 3110474

Page 16: ......