4

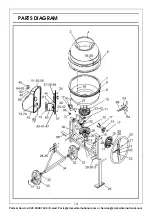

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

18. Never put any tools or other objects in or around the drum while it is

rotating.

19. Never wear jewellery or loose clothing that could be snagged by any part

of the rotating drum.

20. Never load the drum when the machine is switched off. Always switch on

and ensure the drum is rotating before loading.

21. Do not operate this machine on a gradient. Always stand the mixer on firm,

level ground where it cannot tip over.

22. Always switch off and disconnect from the power supply before moving

the machine around the work site.

23. Never use the mixer if the power cable or other important parts of the

machine are damaged.

24. If an extension cable is used, the cable and plug must be of watertight

construction. Inadequate extension cables can be dangerous.

SAFETY SYMBOLS

T

he following symbols are shown on the product or it’s packaging.

Read instruction

manual before use

CE Mark

Sound Power Rating

label

Falls within Waste

Electrical Equipment

(WEEE) Directive

Wear Gloves

Wear eye protection

Wear protective

footwear

Wear protective head

wear

Class II product not

requiring an earth

connection.