4

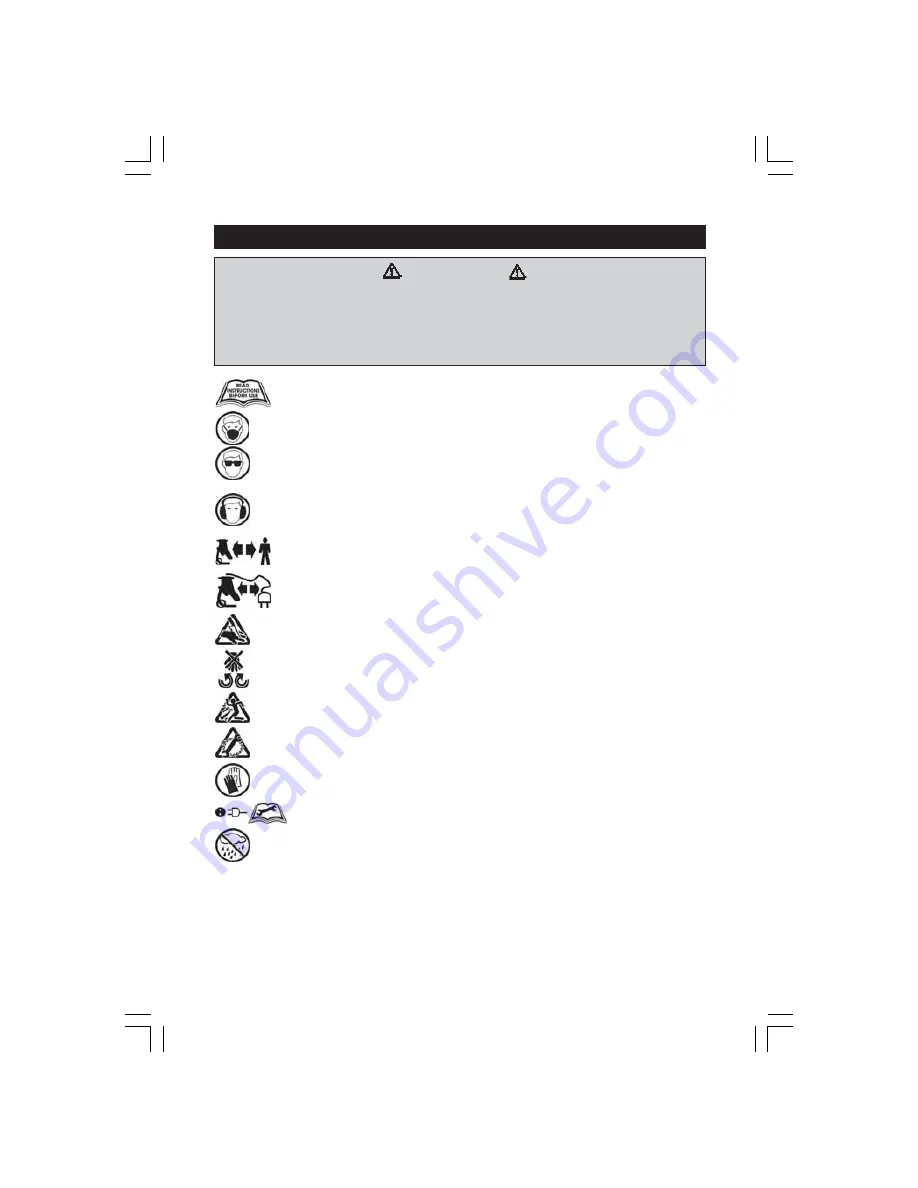

GENERAL SAFETY PRECAUTIONS

•

ALWAYS

learn the machines applications, limitations and specific potential hazards

peculiar to it. Read and become familiar with the entire operating manual.

•

ALWAYS

use a face or dust mask.

•

ALWAYS

wear safety goggles, manufactured to the latest European safety

standards. Everyday glasses do not have impact resistant lenses, they are NOT

safety glasses.

•

ALWAYS

wear ear protectors/defenders as the noise level of this machine can

develop considerable noise - see specifications.

•

ALWAYS

keep people at a safe distance from the work area, especially whilst

operating the machine. Children should not be allowed in the work area

•

ALWAYS

keep the mains cable away from the hopper/cutter blades. Follow

maintenance instructions.

•

NEVER

put your hands near the blades

•

NEVER

put your hands into hopper near the rotating blades

•

ALWAYS

be aware of flying chips and debris

-NEVER

peer into the hopper when

inserting material - keep your head well away.

•

ALWAYS

Ensure the blades have stopped before carrying out inspection or

maintenance

•

ALWAYS

wear a good pair of industrial gloves when using this machine

•

ALWAYS

disconnect the machine from the power supply before servicing or

cleaning etc.

•

NEVER

use power tools in damp or wet locations or expose them to rain.

WARNING

:

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE OPERATING

As with all machinery, there are certain hazards involved with their operation

and use. Exercising respect and caution will considerably lessen the risk of per-

sonal injury. However, if normal safety precautions are overlooked or ignored,

personal injury to the operator or damage to property, may result.

•

ALWAYS

ensure the ON switch is OFF before plugging into the mains. Avoid accidental starting.

•

ALWAYS

concentrate on the job at hand, no matter how trivial it may seem. Be aware

that accidents are caused by carelessness due to familiarity.

•

ALWAYS

wear proper apparel. Loose clothing or jewellery may get caught in moving

parts. Wear protective hair covering to contain long hair.

Summary of Contents for CGS40

Page 2: ...2 ...

Page 9: ...PARTS DIAGRAM 10 ...