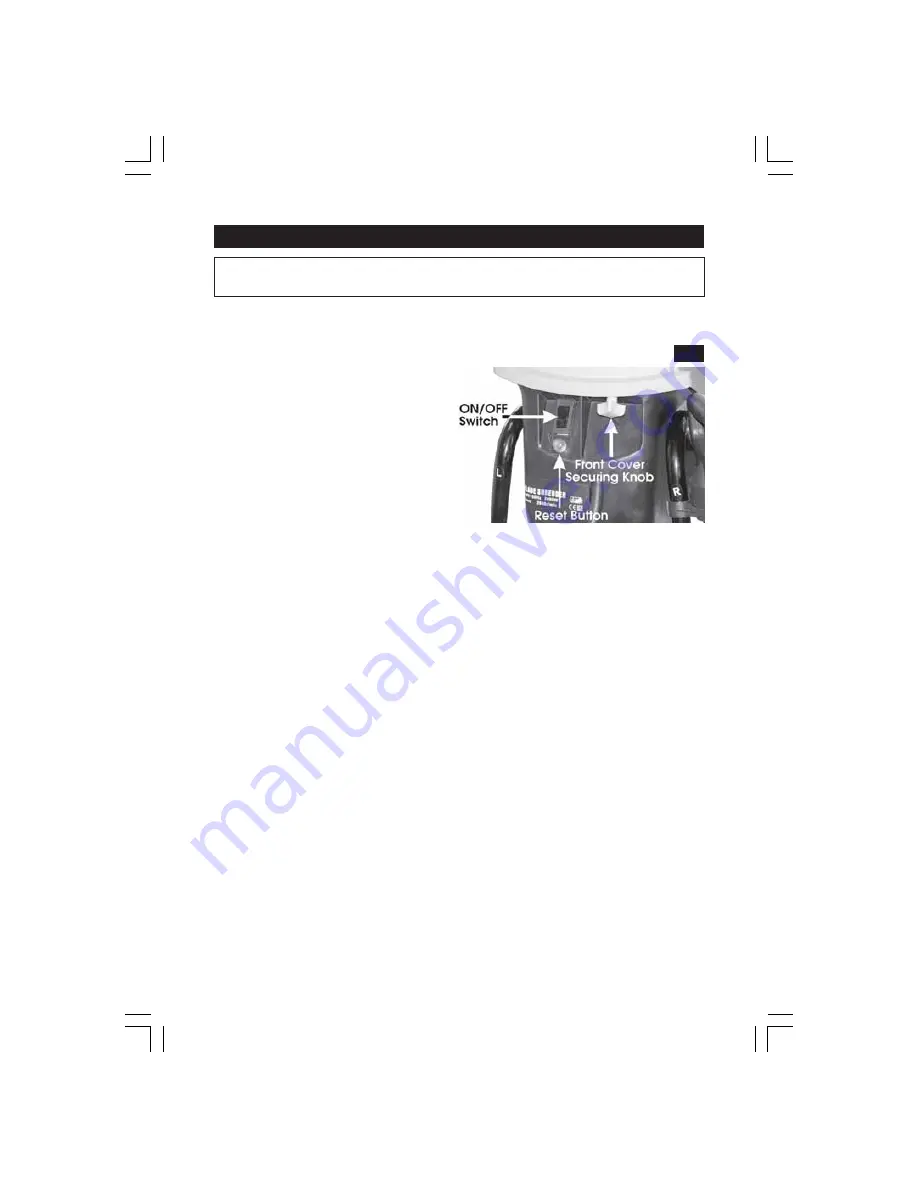

OPERATION

With the machine standing on firm level ground, standing on a board if necessary, plug the

machine into the mains supply, via a residual current device (RCD), and start the machine

by pressing the ON/OFF rocker switch shown below, to ON.

If the machine fails to start, check to ensure

the front cover is firmly secured by

tightening, if necessary, the front cover

securing knob - see illustration.

NOTE: The front cover securing knob

incorporates a microswitch, which prevents

the shredder from operating if the front

cover is not properly secured.

When the machine is running at full speed,

proceed to feed material into the hopper,

DO NOT force it. The cutter blades will pull

the material into the machine, but small,

light material, leaves etc., may need

pushing in with the Push Stick - NEVER push material into the hopper with your hands.

The material must be of a size to easily enter the holes in the hopper - max. 40mm.

All side shoots, branches etc., must be cut off beforehand.

Please take note of the safety precautions, and DO NOT attempt to shred hard materials,

such as glass, metal, bones, plastic, polythene, rope etc.

Be aware that treated wood when shredded could produce toxic dust, as could prunings

with fungus or decay. These materials should not be shredded but taken to the recycling

centre.

Place a collecting bag, or bin below the chute to collect chippings.

IMPORTANT!

Should the machine become clogged and stop delivering chippings, switch OFF

immediately and disconnect from the mains supply.

Undo the front cover securing knob fully and open the cover. Using industrial quality gloves,

remove any material in the chute. Take great care to avoid contact with the cutter blades

- use a stick where necessary.

Ensure the cover is properly secured before plugging into the mains supply and restarting.

OVERLOAD PROTECTION

Should the machine become overloaded or overheat, a Thermal Overload will intervene,

shutting off the machine.

Should this occur, switch OFF the machine and disconnect from the mains supply, open the

front cover and remove any material in the chute, then replace the cover.

Allow the machine to cool for at least 5 minutes before plugging into the mains supply,

pressing the RESET button, see illustration above and restarting.

F

ig.5

7

CAUTION

Always wear proper safety goggles, and ear defenders .

Summary of Contents for CGS40

Page 2: ...2 ...

Page 9: ...PARTS DIAGRAM 10 ...