-6-

4.

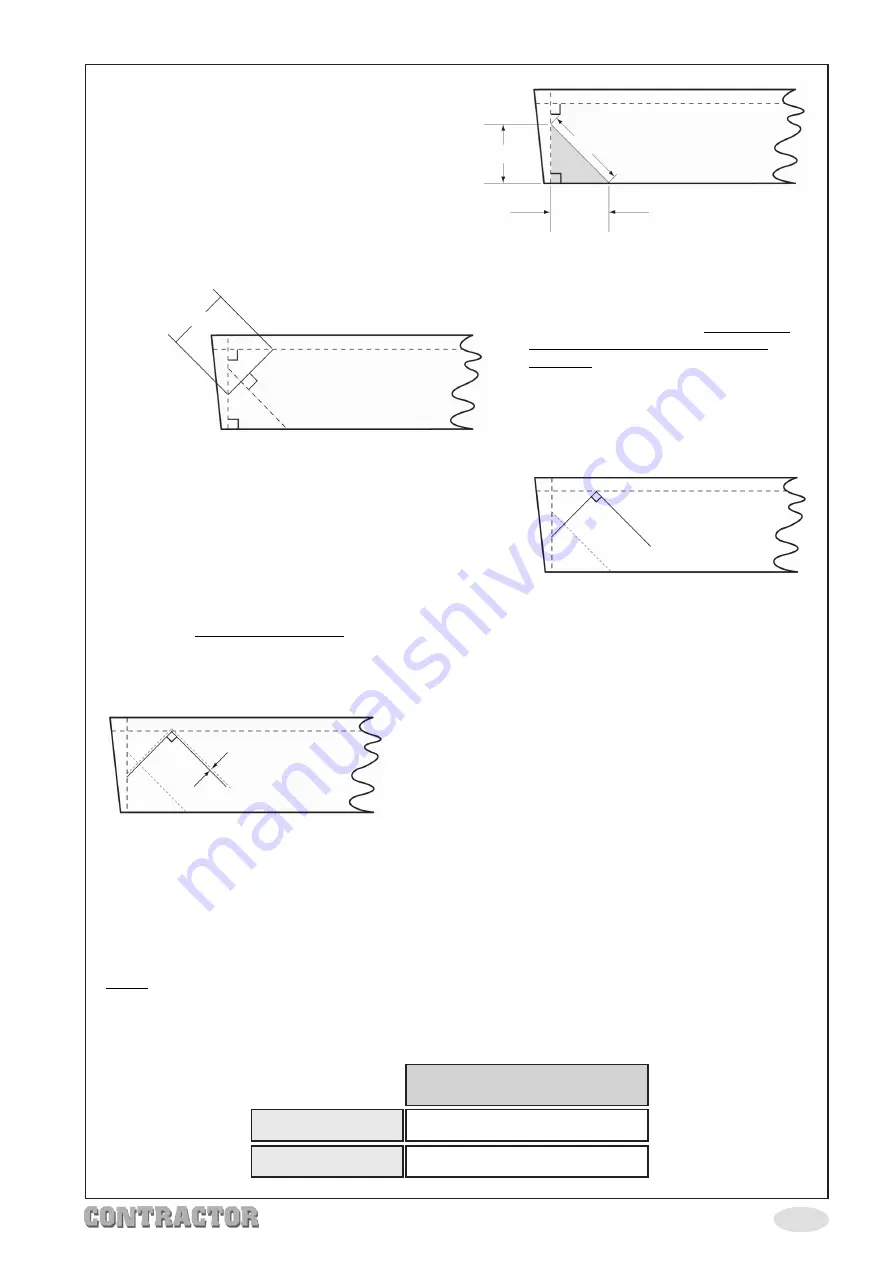

Measure from the right angled line

along the side of the string, the going

length and mark this point. From the

same corner point intersection, measure

across the end along the right angled

line, the rise, and mark this point. Now

draw a line between these two points.

This line creates your pitch angle.

(Measure pitch line and note for point

15 - page 8).

FIRST RISER

AT BASE OF

STAIRS

5

.

To find your start point along the

margin, you need to draw a line at

right angles to this pitch angle line.

This line must be no less than the

length of the rise and must be at

right angles with the pitch line

angles. The intersection of this line

(The first riser line) with the margin

will be your start point and the angle

at which this line is drawn will be the

angle to set the jig.

6.

Finally, mark a line (The first tread line) at right

angles to the first riser line from the

intersection point with the riser and the pitch

line.

Setting Up the Jig

7.

The final thing to calculate is the offset value

between the edge of the cutter and the

edge of the jig cut out.

8.

This offset value varies according to which

tread thickness you require.

9.

Select from the table (page 7) the tread

thickness and nose projection you require. As

a general rule the nose projection equals the

tread thickness. This will tell you which cutter

size to use and the resultant offset value

required to set the jig. Refer back to the table

to determine which guide bush and cutter

to use, before cutting.

10.

Mark the offset value against the first riser and the first tread line as shown in the

diagram above.

NOTE:

If a 30mm guide bush is going to be used instead of the supplied guide bushes,

then refer to table below.

38mm Fixed Nose

Ø16mm Cutter

25.4mm tread - 8mm offset

Ø22mm Cutter

32mm tread - 5mm offset

Pitch Angle Line

Offset Value

Rise

Going