9

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

BEFORE USE

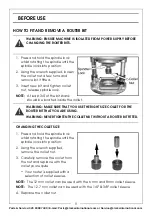

HOW TO FIT AND REMOVE A ROUTER BIT

1. Press and hold the spindle lock

whilst rotating the spindle until the

spindle locks into position.

2. Using the wrench supplied, loosen

the collet nut a few turns and

remove bit if fitted.

3. Insert new bit and tighten collet

nut, release spindle lock.

NOTE:

At least 3/4 of the bit shank

should be located inside the collet.

CHANGING THE COLLET SIZE

1. Press and hold the spindle lock

whilst rotating the spindle until the

spindle locks into position.

2. Using the wrench supplied,

remove the collet nut.

3. Carefully remove the collet from

the nut and replace with the

collet you require.

• Your router is supplied with a

selection of collet sleeves.

NOTE:

The 12 mm collet can be used with the 6 mm and 8mm collet sleeve.

NOTE:

The 12.7 mm collet can be used with the 1/4" & 3/8" collet sleeve

4. Replace the

collet

nut.

WARNING: ENSURE MACHINE IS ISOLATED FROM POWER SUPPLY BEFORE

CHANGING THE ROUTER BITS.

WARNING: MAKE SURE THAT YOU USE THE RIGHT SIZE COLLET FOR THE

ROUTER BIT THAT YOU ARE USING.

WARNING: NEVER TIGHTEN THE COLLET NUT WITHOUT A ROUTER BIT FITTED.

Summary of Contents for Contractor CR3

Page 20: ......