7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

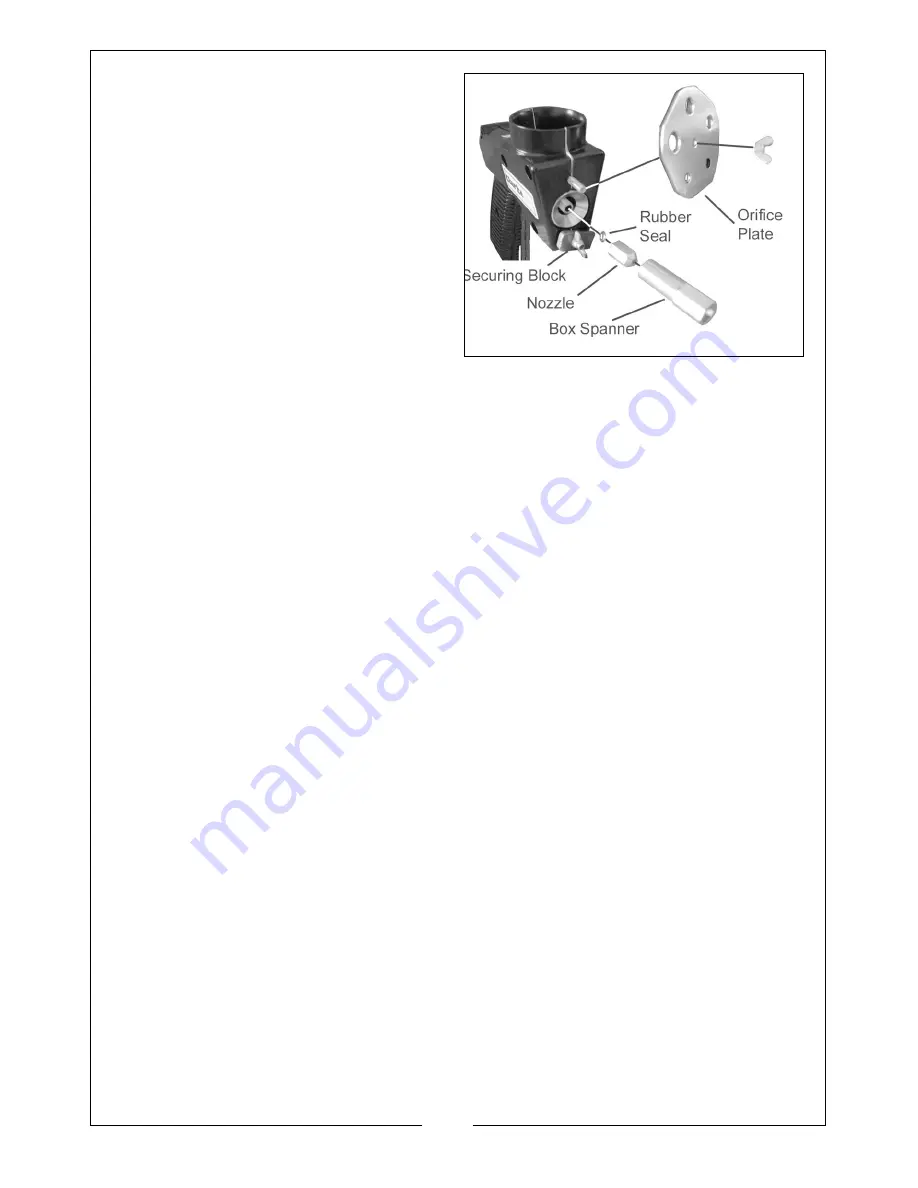

3. Loosen the securing block (34),

and remove the orifice plate (31).

Unscrew the nozzle (18) currently

fitted and screw the chosen nozzle

onto the end of the inlet tube (30),

taking care not to lose the white

rubber seal ring (42) from inside the

nozzle. Tighten the nozzle with the

box spanner (28) stored inside the

handle. Replace the orifice plate

and securing block.

NOTE:

The largest (3.6 mm) nozzle

cannot be tightened with the

box spanner. Instead, the 4mm Allen key must be used.

CONNECTING AND FILLING

1. Connect the air hose using an appropriate connector as necessary. An air

regulator can be fitted to the gun first, which can be used to control the

droplet size produced by the spray gun, turning clockwise to restrict the air

flow. (The greater the flow, the smaller the droplet).

2. Turn the air supply on and check the functionality of the gun by squeezing

the trigger before filling with paint etc.

3. Turn air off and fill hopper with material to be sprayed, (1.75 gallons max)

Always mix the paint to the correct viscosity for spraying according to the

manufacturer’s instructions. (DO NOT OVERFILL - the more paint the heavier

the spray gun).

4. Hold the gun approximately 12” from wall to be covered, supporting the

gun using the handle on the hopper.

5. Gently squeeze the trigger until resistance is felt whilst moving the gun from

side to side. Check the coverage and change the orifice/nozzle size if

necessary, or adjust the air flow regulator adjustment, if fitted.

6. Before using the gun, practice getting the feel of the trigger with the

chosen settings.

7. The trigger stop can be used in order to select the same setting for repeat

operations. Wait until the trigger is in the desired position before tightening

the wingnut (8) to limit trigger movement.

SPRAYING DIFFERENT MATERIALS

The paint flow from the gun is adjustable. This is achieved by turning the orifice

plate to a different setting and replacing the nozzle with one of a different size

as above. If a pressure regulator is used this can also be adjusted to increase

or reduce airflow, according to the material being sprayed.

Summary of Contents for CTG8

Page 12: ......