Page -16-

Clarke

®

Operator's Manual -Encore S28XP/S33XP/S38XP

HOW TO OPERATE THE MACHINE (cont.)

HOW TO CLEAN A FLOOR

WARNING: Water solutions or cleaning mate-

rials used with this type of machine

can leave wet areas on the floor

surfaces. These areas can cause a

dangerous condition for the opera-

tor or other persons. Always put

CAUTION signs near the area you

are cleaning.

To clean a floor, follow this procedure:

1. Put the water and a cleaning chemical in the clean

solution tank.

2. Turn the key switch "ON".

3. Lower the squeegee.

4. Put the brush switch in the "DOWN" position.

5. Turn the solution knob to the right to activate the flow

of solution. Adjust the flow of clean solution to the

flow desired.

6. Move the machine across the floor in the forward

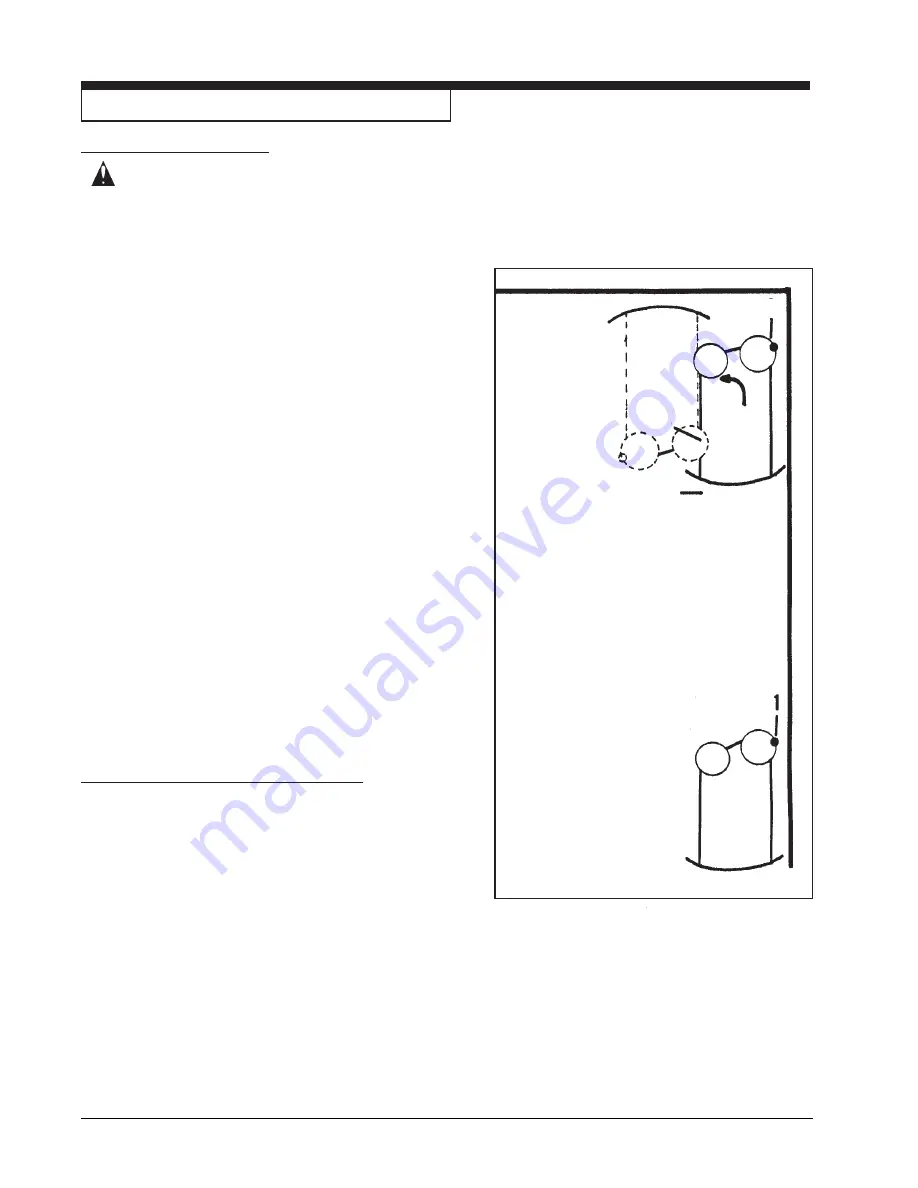

direction. See figure #23 (1).

7. When the machine is one machine length from the

end of the area to be cleaned (figure #23 (2)), rotate the

solution knob to the left.

8.

Make a 180

0

turn. See figure #23 (3).

NOTE:

When you make more passes across the floor, let

the brushes clean approximately 2 inches of the

area already cleaned by the brushes. See figure

#23 (4).

NOTE:

During most cleaning procedures, apply and

remove the solution in one operation.

HOW TO CLEAN A VERY DIRTY FLOOR

To clean a very dirty floor, follow this procedure:

1. Apply solution to the floor.

2. Do not lower the squeegee.

3. Do not activate the vacuum motor.

4. Lower the brushes and scrub the floor.

NOTE: Additional brush pressure may be applied (see

section on How To Operate Scrub Deck).

5. Leave the solution on the floor long enough for the

solution to begin cleaning the floor.

6. Scrub the floor again with additional solution, picking

up all the solution with the squeegee

Figure #23

3

4

2