Clarke

®

Operator's Manual - BOOST 28

Page -11-

Figure 8B

How To Install The Batteries

This machine uses either two 12-volt batteries or four - 6

volt batteries. The batteries are located in the battery

compartment under the recovery tank.

To install the batteries, follow this procedure:

1. Turn machine off. Set brake (if equipped).

2. Make sure recovery tank is empty.

3. Tip up the recovery tank until it locks in the full open

position. See figure 8A.

CAUTION:

Before raising the tank, be sure

tank is empty.

NOTE:

There is an intermediate position available

for holding the recovery tank open for charging

batteries. See figure 8B.

WARNING:

Do not operate or perform mainte-

nance on the machine while the

recovery tank is in the intermediate

position. The tank can be acciden-

tally bumped and it may slam shut.

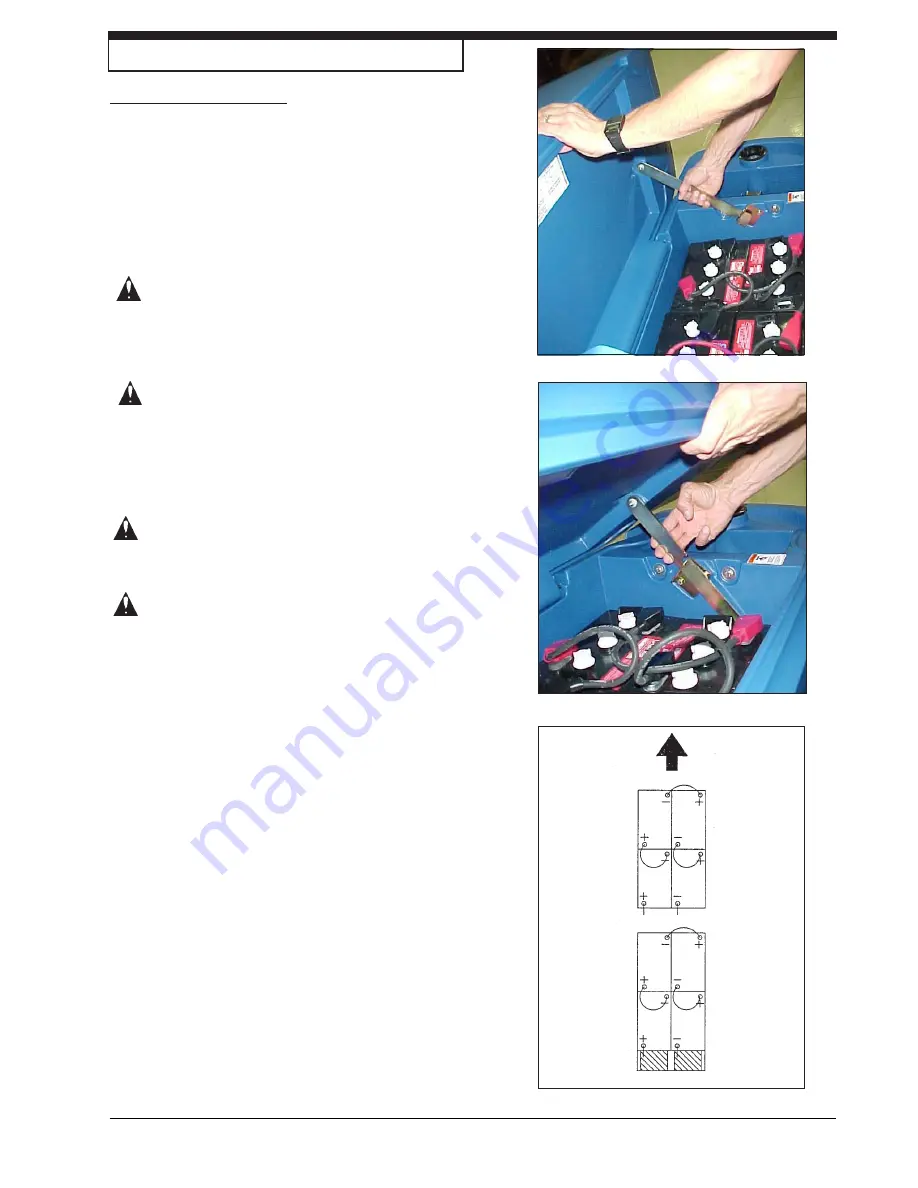

4. Place the batteries in the tray as shown in

figure 8C.

WARNING:

The batteries are heavy. Lifting

batteries without help could result in

an injury. Get help to lift the batter-

ies.

WARNING:

Working with batteries can be

dangerous. Always wear eye

protection and protective clothing

when working near batteries. NO

SMOKING!

5. Connect the cables between batteries and install

long battery cable assembly as indicated. See

figure 9.

6. Join the connector from the battery pack to the

connector on the control panel.

7. Close recovery tank by pulling up on the latch arm

and then slowly lowering the tank.

NOTE:

Charge the batteries before using the

machine.

How To Prepare the Machine For Operation

Figure 9

Figure 8A

Summary of Contents for Focus II Mid-Size Autoscrubber Boost 28

Page 46: ...Clarke Brush Head Assembly Parts List 9 05 Page 46 Clarke Operator s Manual BOOST 28 55 56...

Page 50: ...Page 50 Clarke Operator s Manual BOOST 28 Clarke Transaxle Drawing 9 05...

Page 52: ...Page 52 Clarke Operator s Manual BOOST 28 Clarke Connection Diagram 9 05...

Page 53: ...Clarke Operator s Manual BOOST 28 Page 53 Clarke Electrical Schematic 9 05...

Page 54: ...Page 54 Clarke Operator s Manual BOOST 28 NOTES...