2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

INTRODUCTION

Thank you for purchasing this CLARKE Hippo submersible pump. Hippo 2 has

the same specification as the Hippo 2A but without a float switch.

The Hippo 2 can be supplied for either 110V (part No 7230023) or 230V (part

No 7230024) power supplies.

This pump is designed for pumping clean water.

It is NOT designed for pumping slurry, sludge, mud or heavily polluted water, or

any water containing chemicals or other acidic contaminants including salt

water.

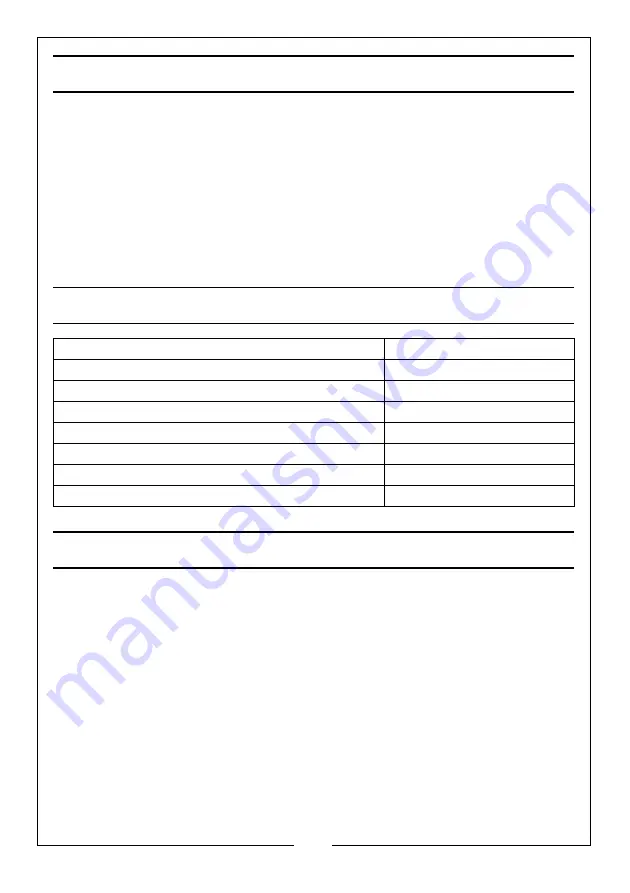

SPECIFICATIONS

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

Voltage

230V~50Hz or 110V

Outlet Thread Diameter

1“BSP

Power 250W

Maximum Head Height

6 m

Maximum Output Flow

85 l/min

Weight

3.65 kg

Cable Length

6 m

Dimensions (L x W x H)

158 x 143 x 265 mm

Summary of Contents for HIPPO 2

Page 12: ......