3

C = base engine series (.85L LP30, 1.248

LP60)

2 = number of cylinders

A = Air cooled

LP = LPCB Loss Prevention Council Board

Approved (NL = Non-Listed)

30 = A power rating code

Lombardini Identification Plate: The second

identification plate contains the Lombardini Model

Number and Serial Number. The identification plate

is located on the right side front of the engine for the

LP30 and the front of the engine for the LP60.

1.2

SAFETY/CAUTION/WARNINGS

ATTENTION: This engine has components and

fluids that reach very high operating temperatures

and is provided with moving pulleys and belts.

Approach with caution. It is the responsibility of the

builder of the machine using a Clarke engine to

optimize the application in terms of maximum end

user safety.

BASIC RULES

The following recommendations are given to reduce

the risk to persons and property when an engine is in

service or out of service.

Engines must not be used for applications other than

those declared under “Scope of Supply”.

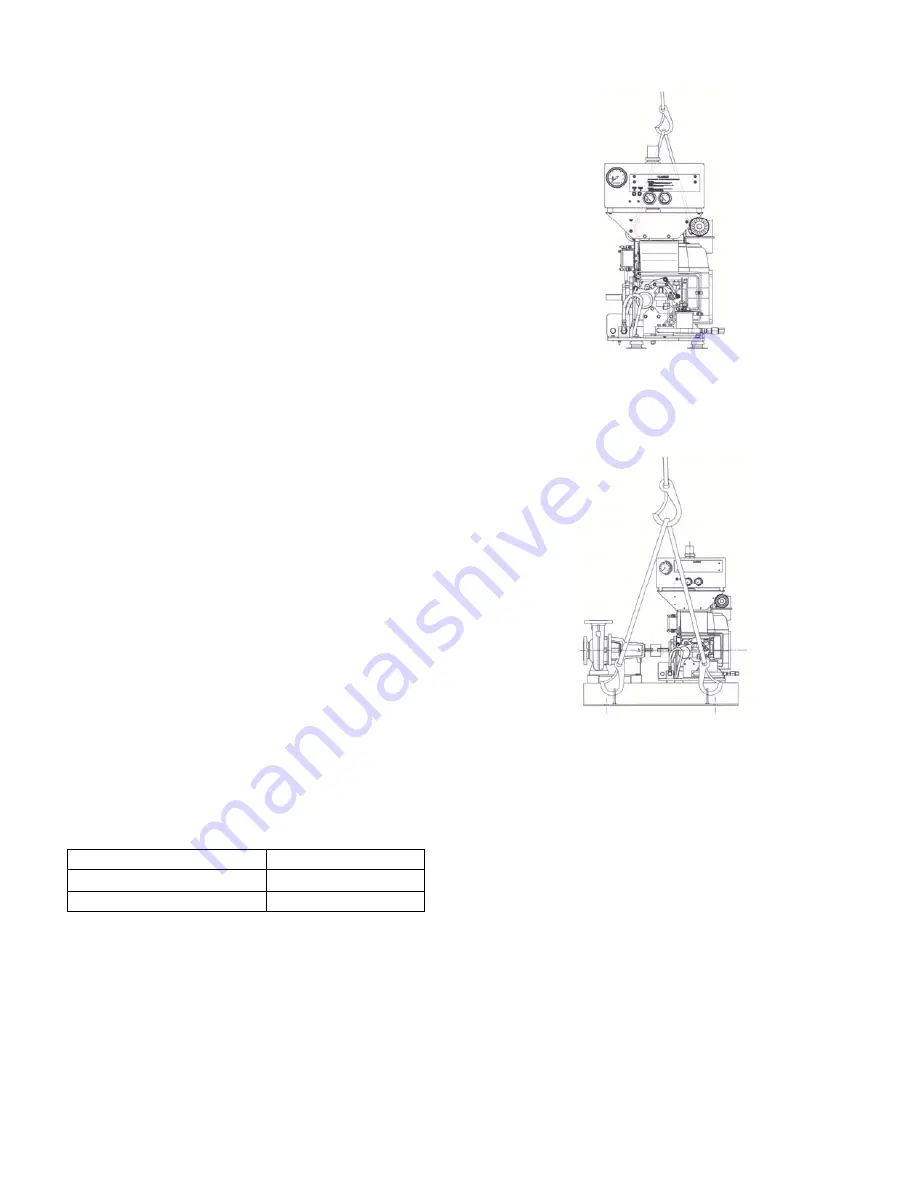

Incorrect handling, modifications and use of non-

original parts may affect safety. When lifting the

engine, take care to use suitable equipment to be

applied to the points specially provided as shown on

the appropriate Engine Installation Drawing. Engine

weights are shown in

figure #2

ENGINE MODEL

WEIGHT kg (lbs)

LC2A – LP 30

104 (229)

LC2A - LP60

151 (333)

Figure #2

Figure #3

shows the typical lifting arrangement of a

bare engine. Note the lifting points on the engine are

for lifting the engine only.

Caution, when lifting, lift

point should always be over the equipment Center of

Gravity.

Figure #3

Figure

#4 shows the typical lifting arrangement of a

base mounted engine and pump set when the base (or

module) is furnished with lifting holes.

Figure #4

When Clarke furnishes the base (or module) for the

engine and pump set, the combined weight of the

engine and base (or module) will be indicated on the

unit.

Caution, when lifting, lift point should

always be over the equipment Center of Gravity.

Note: The engine produces a noise level exceeding

70 dB(a). When performing the weekly functional

test, it is recommended that hearing protection be

worn by operating personnel.

CLARKE UK provides the machine manufacturer

with a “Declaration of Incorporation”

for the Engine, when required, a copy of which is

enclosed in the manual. This document clearly states

the machine manufacturers’ duties and

responsibilities with respect to health and safety.

Refer to

Figure #5.