21

MAINTENANCE

CLEANING

The inside of the stove may require regular cleaning, especially during periods

of peak use, the frequency of this being indicated by experience. It is

advisable to wear a dust mask, protective gloves and safety glasses when

cleaning.

Use a stiff brush and industrial type vacuum cleaner to dislodge and remove

as much material as possible, starting at the top of the stove and working

down to the bottom. Particular attention should be given to the air inlet

controls which can become obstructed. A CVAC Ash Can Filter and vacuum

cleaner is ideal for this process.

GENERAL MAINTENANCE

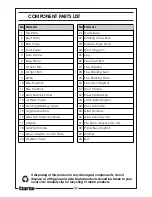

Take this opportunity to check for any damaged parts inside the stove. In the

event of damage or broken components, replacements can be obtained

from Clarke Parts & Service. On no account should unauthorised spare parts

be used.

The stove and flueway should be inspected and maintained when in a cold

condition. NO unauthorised modification of this product should be carried

out. This stove requires regular maintenance by a competent engineer.

STOVE BODY

The stove is finished with a heat-resistant paint which can be cleaned with a

soft brush. Wait until the stove has cooled down before doing this. This finish

can be renovated with Clarke stove paint, although the paint may not be an

exact match and it may be necessary to repaint the complete stove.

If the stove is purely ornamental, painting will provide a durable, attractive

finish. If the stove is used for heating, a high temperature heat resistant paint

(available from your Clarke dealer) must be used, in either aerosol or brush

applied form. Should rust become apparent, clean thoroughly with a wire

brush and apply a suitable anti-rust treatment.

During prolonged periods out of use, the air inlets should be left open and the

door left slightly ajar in order to circulate fresh air and discourage

condensation from forming which could encourage corrosion.

FIRE ROPE

Check the rope around the door and glass. If rope is becoming detached,

replace with rope approved for this purpose.

Inspect the fireproof door seals where fitted, to ensure there is an effective

seal around the door and re-fix it if loose using stove rope adhesive. If in poor

condition it should be replaced.