14

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

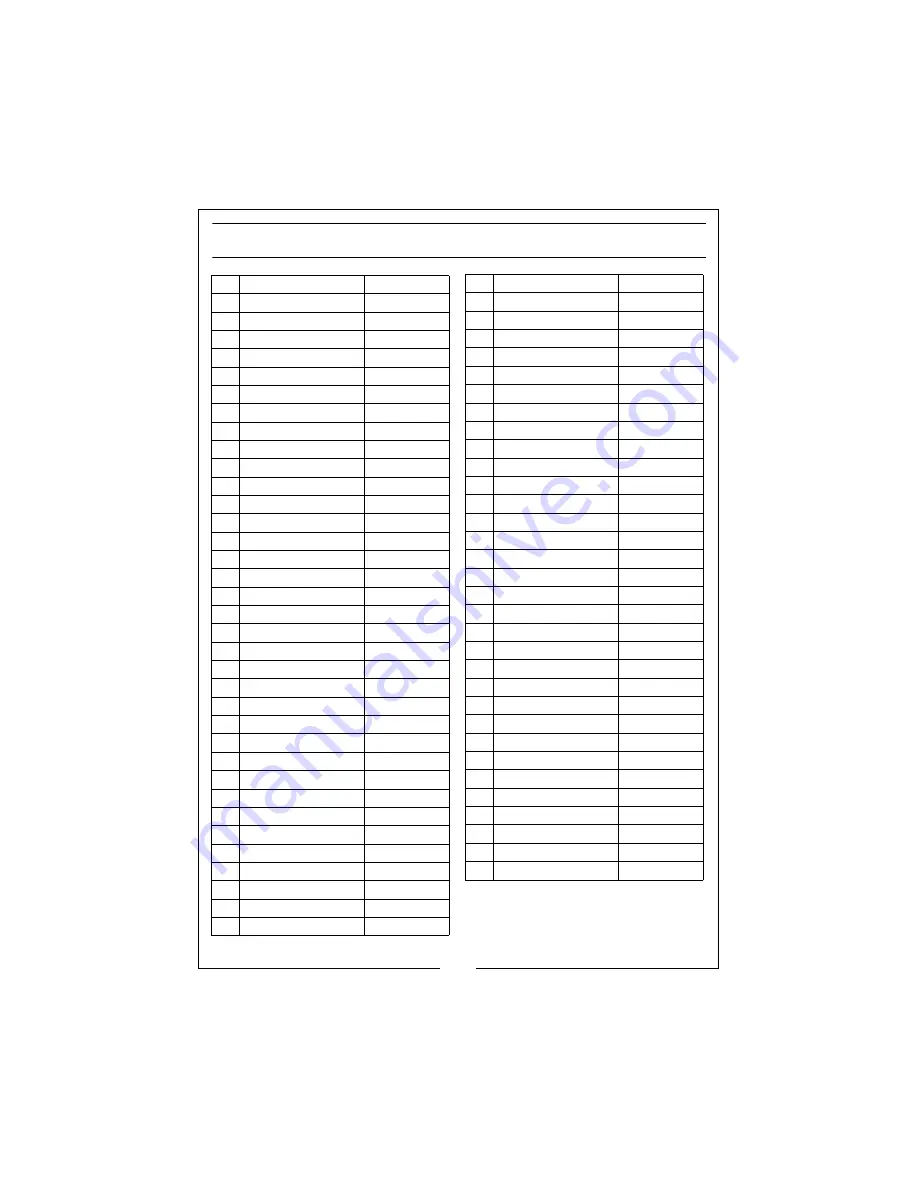

PARTS LIST

1

Phillips Screw Assembly

WACBG6250L01

2

Left Guard Cover

WACBG6250L02

3

I type Hex Nut

WACBG6250L03

4

Wheel Flange

WACBG6250L04

5

Wheel(36#)

WACBG6250L05

6

Phillips Screw

WACBG6250L06

7

Left Guard

WACBG6250L07

8

Left Spark Deflector

WACBG6250L08

9

Flat Washer

WACBG6250L09

10

Phillips Screw

WACBG6250L10

11

L/H Eyeshield mount rod WACBG6250L11

12

Bracket

WACBG6250L12

13

Flat Washer

WACBG6250L13

14

Hex Bolt

WACBG6250L14

15

Dome Screw

WACBG6250L15

16

Eyeshield Plate

WACBG6250L16

17

Big Flat Washer

WACBG6250L17

18

Phillips Screw

WACBG6250L18

19

Phillips Screw

WACBG6250L19

20

R/H Eyeshield mount rod WACBG6250L20

21

End cap

WACBG6250L21

22

I type Hex Nut

WACBG6250L22

23

Wavy washer

WACBG6250L23

24

Ball bearing

WACBG6250L24

25

Stator

WACBG6250L25

26

Rotor

WACBG6250L26

27

Nut

WACBG6250L27

28

Lock Nut

WACBG6250L28

29

L/H work rest

WACBG6250L29

30

Eyeshield WACBG6250L30

31

Work Rest Lock knob

WACBG6250L31

32

Standard Washer

WACBG6250L32

33

Flat Washer

WACBG6250L33

34

I type Hex Nut

WACBG6250L34

35

Nut

WACBG6250L35

36

Wheel(60#)

WACBG6250L36

37

Locked Nut

WACBG6250L37

38

Toothed Locking Washer WACBG6250L38

39

Phillips Screw

WACBG6250L39

40

Right Guard

WACBG6250L40

41

Cable Grommet

WACBG6250L41

42

Capacitor

WACBG6250L42

43

Capacitor holder

WACBG6250L43

44

Washer

WACBG6250L44

45

Dressing Wheel

WACBG6250L45

46

Lamp Assembly

WACBG6250L46

47

Motor housing

WACBG6250L47

48

Cord & Plug

WACBG6250L48

49

Strain relief

WACBG6250L49

50

Nut

WACBG6250L50

51

Toothed Locking Washer WACBG6250L51

52

Switch Plate

WACBG6250L52

53

Switch

WACBG6250L53

54

Hex nut

WACBG6250L54

55

Phillips Screw

WACBG6250L55

56

Flat washer

WACBG6250L56

57

Rubber foot

WACBG6250L57

58

Tool tray

WACBG6250L58

59

Base Plate

WACBG6250L59

60

R/H work rest

WACBG6250L60

61

Flat washer

WACBG6250L61

62

Bulb

WACBG6250L62

63

Magnified eye shield

WACBG6250L63

64

Dressing tool base

WACBG6250L64

65

Flat washer

WACBG6250L65

66

Standard Washer

WACBG6250L66

67

Phillips Screw

WACBG6250L67

68

Right Guard Cover

WACBG6250L68

69

Right Spark Deflector

WACBG6250L69

Summary of Contents for Metalworker CBG6250L

Page 16: ......