12

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

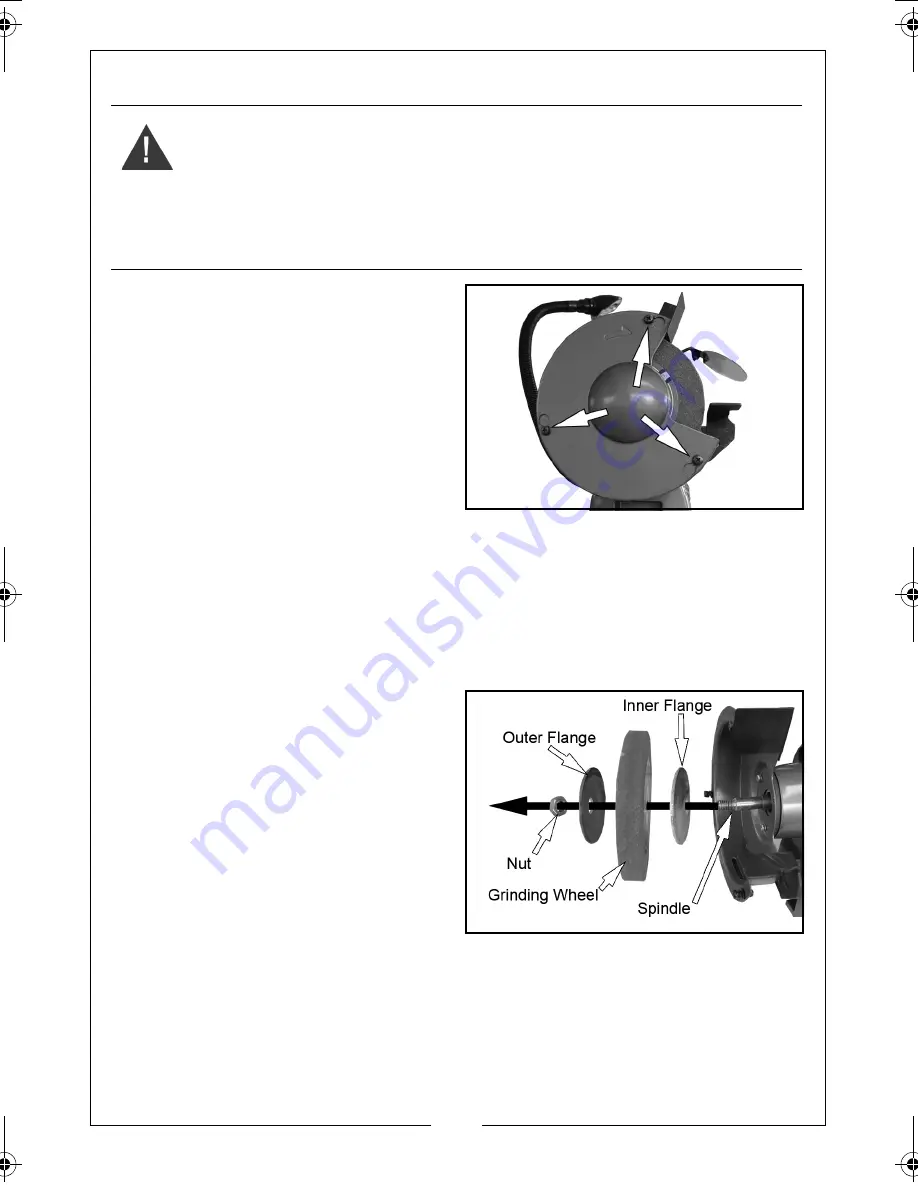

REPLACING THE WHEELS

1. Loosen the screws shown and

rotate and remove the cover.

2. Hold the other wheel by hand, and

remove the nut and outer flange.

NOTE:

The left hand wheel locking

nut has a left handed thread.

3. Slide off the old wheel and replace

with a new one.

• Use only wheels recommended

by the manufacturer which have a marked speed equal to or

greater than the speed marked on the nameplate of the tool

• The disc should have maximum dimensions of 150 mm diameter, 20

mm thick with a bore size of 12.7 mm.

• Inspect the wheel for cracks, chips or any other visible damage,

damaged abrasive products must be destroyed and discarded

4. Replace the outer flange.

• Make sure both wheel flanges

are placed with the concave

sides towards the wheel.

5. Replace the nut securely.

• Do not overtighten as this may

damage the grinding wheel.

6. Re-assemble the guards fully prior

to carrying out testing.

• Each time after mounting, the wheel should be test run for a

reasonable time (approximately 1 minute).

WARNING: THE POSITIONS OF THE GRINDING WHEEL AND WIRE WHEEL

SHOULD NOT

BE INTERCHANGED, AS THIS MAY RESULT IN INJURY OR

DAMAGE TO THE PRODUCT

WARNING: DO NOT USE DAMAGED GRINDING WHEELS.

WARNING: SWITCH THE GRINDER OFF AND DISCONNECT THE POWER

SUPPLY BEFORE CHANGING THE GRINDING WHEELS

CBG6250LW Bench Grinder.fm Page 12 Thursday, November 10, 2011 2:59 PM

Summary of Contents for Metalworker CBG6250LW

Page 16: ......