22

In order to change the gears, ensure the machine is switched OFF and disconnected

from the mains supply.

Remove the gear train cover which is secured with two hex. socket head screws.

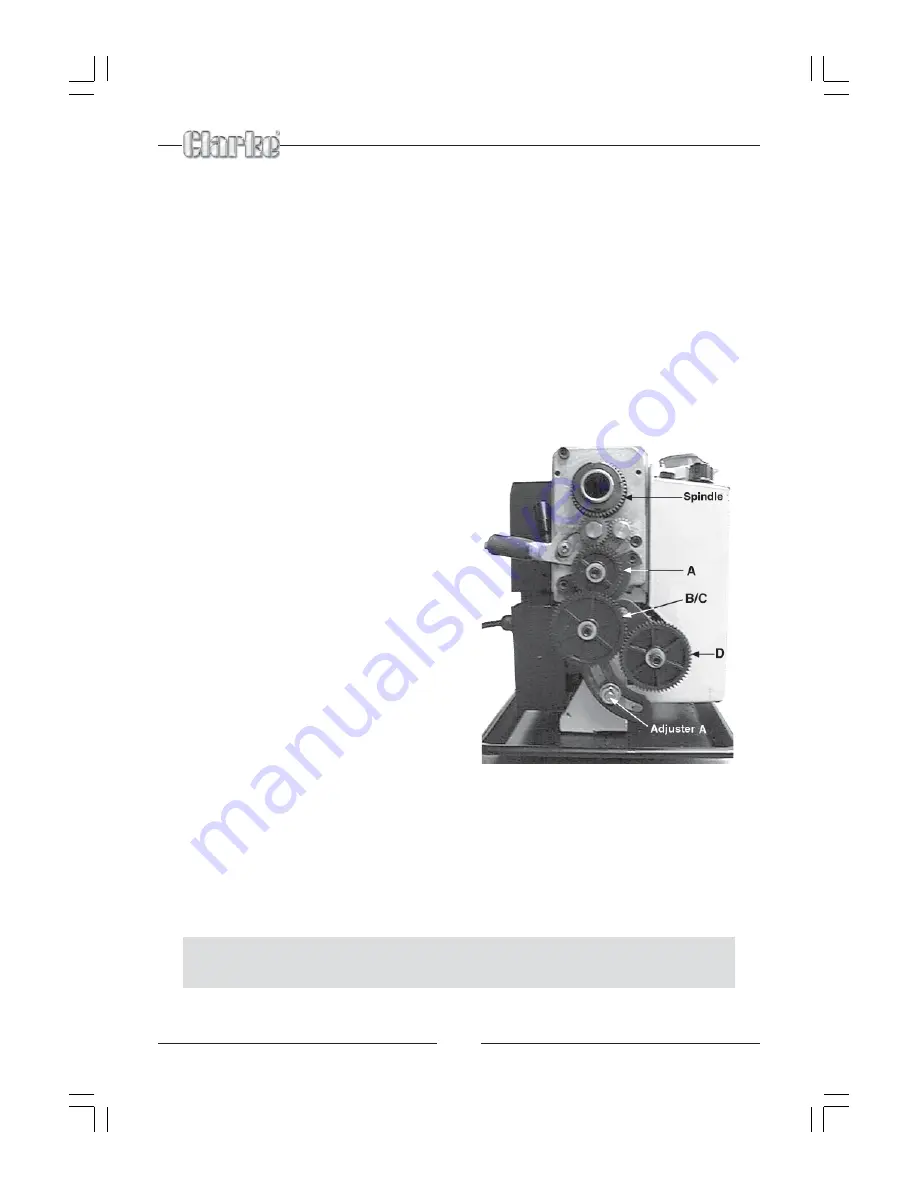

Gear A may be considered as the Driver, and Gear D as the Driven gear.

When a Simple gear train is configured, as illustrated in Fig. A, page 19, the gear at

B acts as an Idler and its size is therefore irrelevant - any convenient gear will suffice

to connect A and D. This is denoted by a blank space in the column in the gear

chart.

The positions of the shafts carrying gears A and D are fixed, therefore all adjustments

are carried out on the shaft carrying gears B and C and the Adjuster ‘A’, shown in

fig. 11.

1.

Unscrew the hex socket head screws,

securing gears A and D, followed by

the screw securing gears B and C.

2.

To allow the gears B andC to

disengage completely and to

provide for easier reassembly,

unscrew the nut securing the shaft

carrying B and C, and the nut

securing the adjuster A.

3.

Remove the gears, taking care to

retain the small keys on each shaft,

and replace with those necessary to

produce your screw thread. They may

be mounted either way round.

The number of teeth on each gear is

clearly marked.

Replace the securing screws,

ensuring the flat washer bears up

against the gear hub in each case.

NOTE: If a compound gear train is required, as

shown in Fig. B on page 18, ensure the spacer,

which is keyed to the shaft carrying gear D, is

located on the shaft, BEFORE the gear, in order

to align gear D with gear C.

4.

Proceed to move the shaft carrying B andC and the adjuster ‘A’ so that all

gears mesh correctly, then tighten the adjuster securing nuts. This may take

one or two attempts but make sure there is as little backlash as possible without

being overtight. (Turn the spindle by hand to test for backlash).

Replace the cover and secure with the two hex socket head bolts.

CAUTION:

NEVER run the machine with the cover removed.

Fig 11

Summary of Contents for MetalWorker CL300M

Page 1: ...1 OPERATING MAINTENANCE INSTRUCTIONS 300mm VARIABLE SPEED METAL LATHE Model No CL300M 1008...

Page 4: ...4...

Page 29: ...29 PARTS DIAGRAM...

Page 30: ...30 WIRING DIAGRAM...

Page 31: ...31 NOTES...

Page 32: ...32...