- 3 -

-12 -

SAFETY PRECAUTIONS

WARNING

As with all machinery, there are certain hazards involved with their operation and use.

Exercising respect and caution will considerably lessen the risk of personal injury.

However, if normal safety precautions are overlooked, or ignored, personal injury to the

operator, or damage to property may result.

It is in your own interest to read and pay attention to the following rules:

1.

COMPRESSED AIR IS DANGEROUS, NEVER

direct a jet of air at people or animals, and

NEVER discharge compressed air against the skin.

2.

DO NOT

operate your compressor with any guards removed.

3.

DO NOT

leave pressure in the receiver overnight, or when transporting.

4.

DO NOT

adjust, or tamper with the safety valves. The maximum pressure is factory set,

and clearly marked on the machine.

5.

DO NOT

operate in wet or damp conditions. Keep the machine dry at all times.

Similarly,a clean atmosphere will ensure efficient operation. Do not use in dusty or

otherwise dirty locations.

6.

DO NOT

exert any strain on electrical cables and ensure that air hoses are not tangled

or wrapped around machinery etc.

7.

ALWAYS

adjust the pressure regulator to the recommended setting for the particular

spray gun or tool being used.

8.

ALWAYS

protect yourself. Think carefully about any potential hazards which may be

created by using the air compressor and use the appropriate protection. e.g. Goggles

will protect your eyes from flying particles. Face masks will protect you against paint

spray and/or fumes.

9.

ALWAYS

make sure that children and animals are kept well away from the compressor

`and any equipment attached to it.

10.

ALWAYS

ensure that all individuals using the compressor have read and fully

understand the Operating Instructions supplied.

11.

ALWAYS

ensure that any equipment or tool used in conjunction with your compressor,

has a safety working pressure exceeding that of the machine.

12. Before spraying any material always consult paint manufacturers instructions for safety

and usage.

13. Some of the metal parts can become quite hot during operation. Take care not to

touch these until the machine has cooled down.

14. When disconnecting air hoses or other equipment from your compressor ensure that

the air supply is turned off at the machine outlet and expel all pressurised air from

within the machine and other equipment attached to it.

15. Electrical or mechanical repairs should only be carried out by a qualified engineer. If

problems occur, contact your Clarke dealer.

16. Before carrying out any maintenance, ensure the pressure is expelled from the air

receiver, and the machine is disconnected from the mains supply.

17. When spraying inflammable materials e.g. cellulose paint, ensure that there is

adequate ventilation and keep clear of any possible source of ignition.

1.

Immerse only the front end of the gun until solvent just covers the fluid connection.

2.

Use a bristle brush and solvent to wash off accumulated paint.

3.

Do not submerge the entire spray gun in solvent because:

a.

the lubricant in the gland packings will dissolve and the packings will dry out.

b.

the lubricant will dissolve causing harder operation and faster wear.

c.

residue from dirty solvent may clog the narrow air passages in the gun.

4.

Wipe down the outside of the gun with solvent dampened rag.

5.

Lubricate gun daily. Use a light machine oil on:

a.

fluid needle packing.

b.

air valve packing.

c.

fan control packing.

d.

trigger pivot point.

Coat the fluid control spring with vaseline.

Caution: Never use lubricants containing silicone as this may cause finish defects.

For a professional looking finish paint must be thinned. If the manufacturers

recommendations on thinning are not available, the following can be used as a general

guide: Water based paints (emulsions)

- 10-20% water

Oil based paints (gloss)

- up to 10% white spirit thinners

Cellulose paints

- up to 50% cellulose thinners

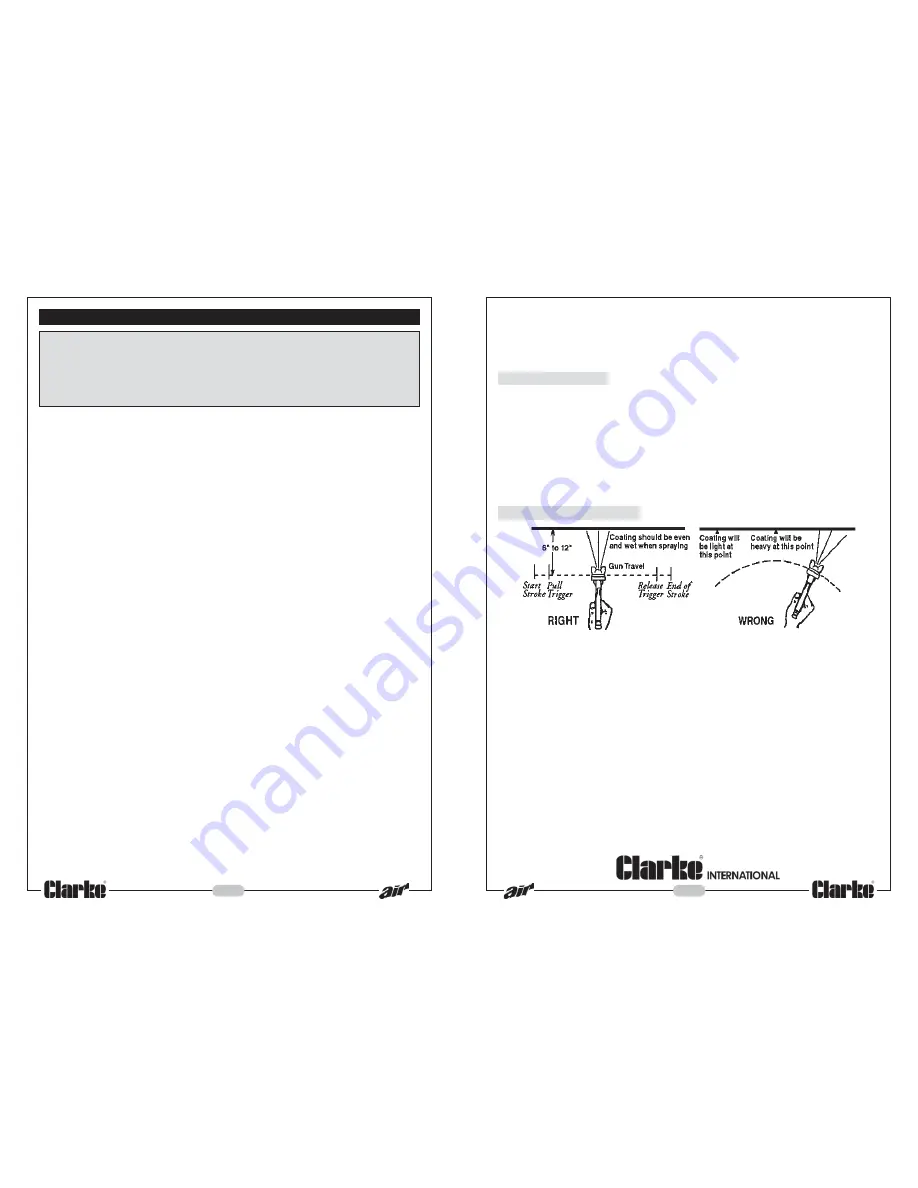

3. Handling The Gun

The first requirement for a good resultant finish is the proper handling of the gun. The gun

should be held perpendicular to the surface being covered and moved parallel to it. The

stroke should be started before the trigger is pulled and the trigger should be released

before the stroke is ended. This gives accurate control of the gun and material.

The distance between gun and surface should be 6 to 12 inches depending on material

and atomizing pressure. The material deposited should always be even and wet. Lap each

stroke over the preceding stroke to obtain a uniform finish.

NOTE: To reduce overspray and obtain maximum efficiency, always spray with the lowest

possible atomizing air pressure.

4. Spray Gun Maintenance