OPERATION

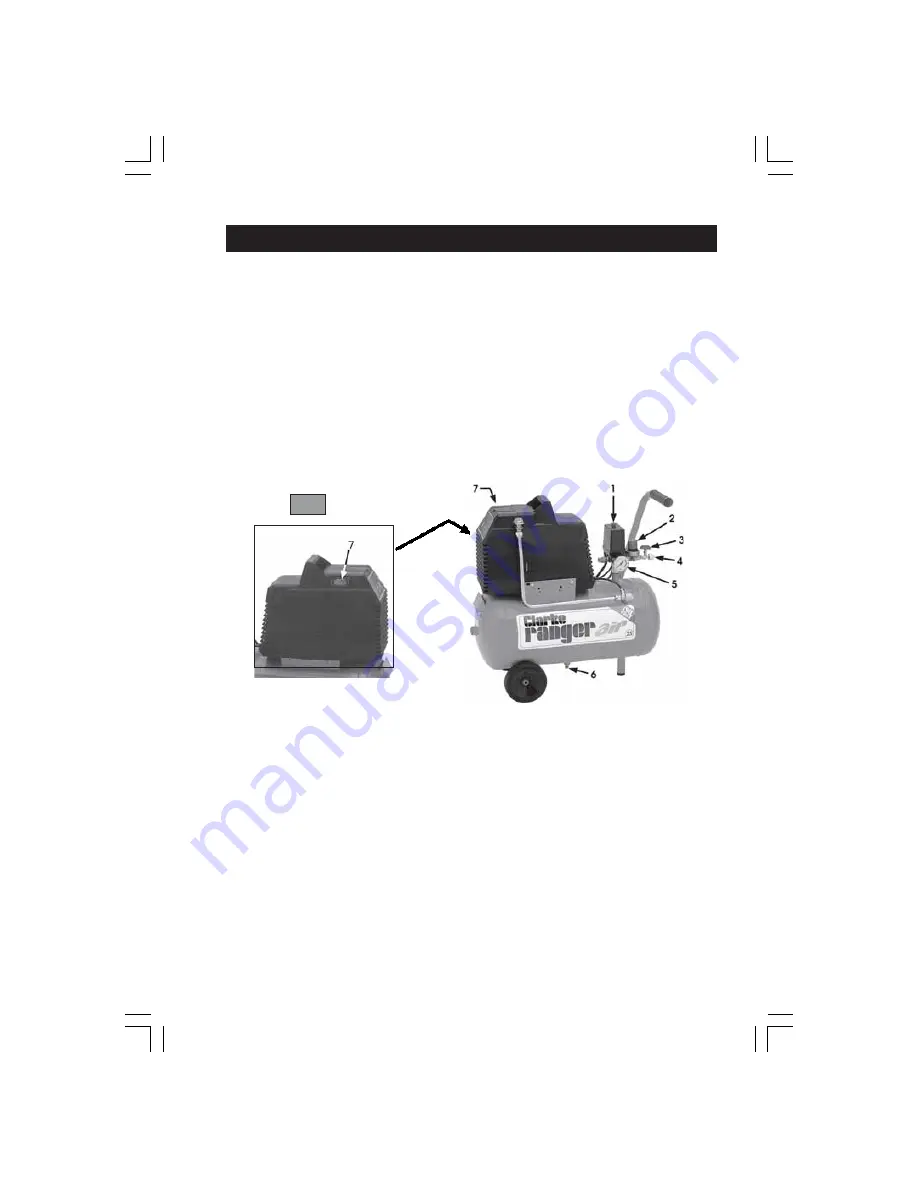

(Numbers in brackets refer to fig. 1 below)

Before connecting your Ranger25 to the mains supply, check the

following:-

•

The mains voltage is 230V.

•

The ON/OFF control knob (1) is in the OFF (lower) position.

•

The pressure regulator (2) should be set at its lowest setting, i.e. turned

fully anticlockwise, and the tap (3) screwed IN to its closed position.

•

If the machine has not been used for 24 hours or so, open the air

receiver drain valve (6) to drain any condensate which may have

accumulated. When clear, close the valve, finger tight.

IMPORTANT: If the receiver is under pressure, keep your hands well away

from the air being expelled.... remember, compressed air is DANGEROUS!

Now connect a suitable air hose, fitted with quick-fit adaptors, between

the air outlet (4) and the spray gun or air tool being used.

Ensure that the rubber washers are in place to form the necessary air tight

seals. These fittings should be screwed by hand but take care not to over

tighten. If a rubber seal is damaged then it should be replaced.

If you do not wish to use the Quick Fit method of hose connection, simply

remove the Quick Fit retaining nut and use an air hose fitted with

conventional 1/4 BSP connectors.

Once the hose connections are complete, CHECK AGAIN to ensure the

pressure regulator (2) is turned fully anticlockwise so that compressed air

cannot reach the air tool, and switch the compressor ON, by lifting the

ON/OFF knob (1), until it clicks into the upper position. The air compressor

will now start, and pressure will build up in the receiver to a regulated

maximum pressure of 115 psi (8 Bar) as indicated on the pressure gauge (5).

Fig.1

7