4. SPRAY GUN MAINTENANCE

1.

Immerse only the front end of the gun until solvent just covers the fluid

connection.

2.

Use a bristle brush and solvent to wash off accumulated paint.

3.

Do not submerge the entire spray gun in solvent because:

a.

the lubricant in the gland packings will dissolve and the packings will dry

out.

b.

the lubricant will dissolve causing harder operation and faster wear.

c.

residue from dirty solvent may clog the narrow air passages in the gun.

4.

Wipe down the outside of the gun with solvent dampened rag.

5.

Lubricate gun daily. Use a light machine oil on:

a.

fluid needle packing.

b.

air valve packing.

c.

fan control packing.

d.

trigger pivot point.

Coat the fluid control spring with vaseline.

Caution: Never use lubricants containing silicone as this may cause finish defects.

For a professional looking finish paint must be thinned. If the manufacturers

recommendations on thinning are not available, the following can be used as a

general guide: Water based paints (emulsions) - 10-20% water

Oil based paints (gloss) - up to 10% white spirit thinners

Cellulose paints - up to 50% cellulose thinners

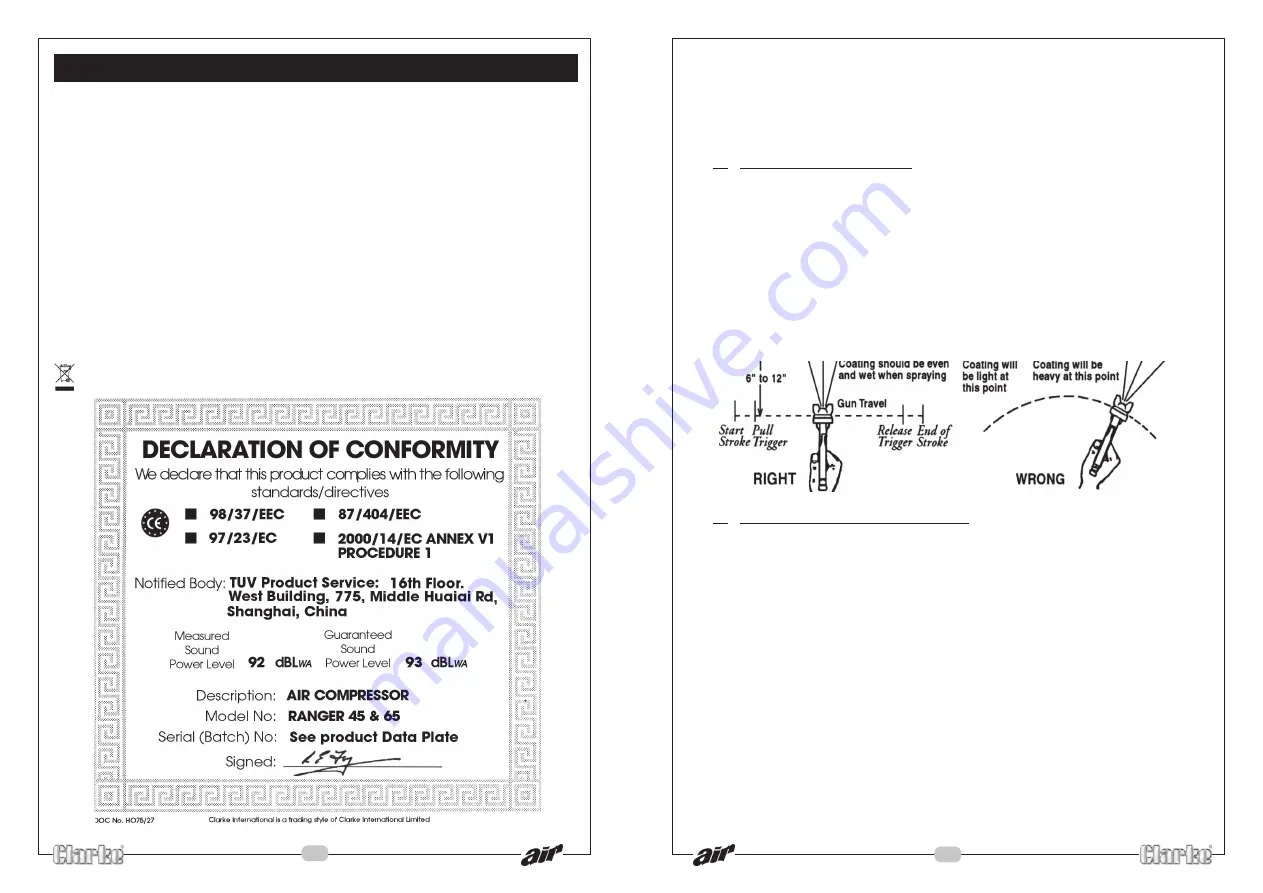

3. HANDLING THE GUN

The first requirement for a good resultant finish is the proper handling of the gun.

The gun should be held perpendicular to the surface being covered and moved

parallel to it. The stroke should be started before the trigger is pulled and the

trigger should be released before the stroke is ended. This gives accurate control

of the gun and material.

The distance between gun and surface should be 6 to 12 inches depending on

material and atomizing pressure. The material deposited should always be even

and wet. Lap each stroke over the preceding stroke to obtain a uniform finish.

NOTE: To reduce overspray and obtain maximum efficiency, always spray

with the lowest possible atomizing air pressure.

15

Engineering Manager

Copyright: Clarke International. May, 2000

SPECIFICATIONS

Electrical Supply ......................................................... 230V, 1Phase 50Hz

Motor Rating ................................................................ 1.5 HP

Max. Air Pressure ........................................................ 8 bar (115 lbf/in

2

)

Air Displacement ........................................................ 7cuft/min

Duty Cycle ................................................................... S1 (continuous)

Operating Temperature .............................................. 0

O

C - 35

O

C

Sound Power Level ..................................................... 93.3dBL

WA

Air Receiver ........... Ranger 45 ................................... 24 litre

Ranger 65 ................................... 50 litre

Nett Weight ............ Ranger 45 ................................... 29.5kg

Ranger 65 ................................... 38kg

Dimensions ............ Ranger 45 ................................... 635x356x600mm

Ranger 65 ................................... 710x380x660mm

Compressor Oil ........................................................... CLARKE SAE 40

Part No. .................. Ranger 45 ................................... 2130005

Please note that the details and specifications contained herein, are correct at the time of going to

print. However, CLARKE International reserve the right to change specifications at any time without

prior notice. Always consult the machine’s data plate

When disposing of this product, ensure it is disposed of according to all local ordinances

2