OPERATION

Fig.1

Fig.2

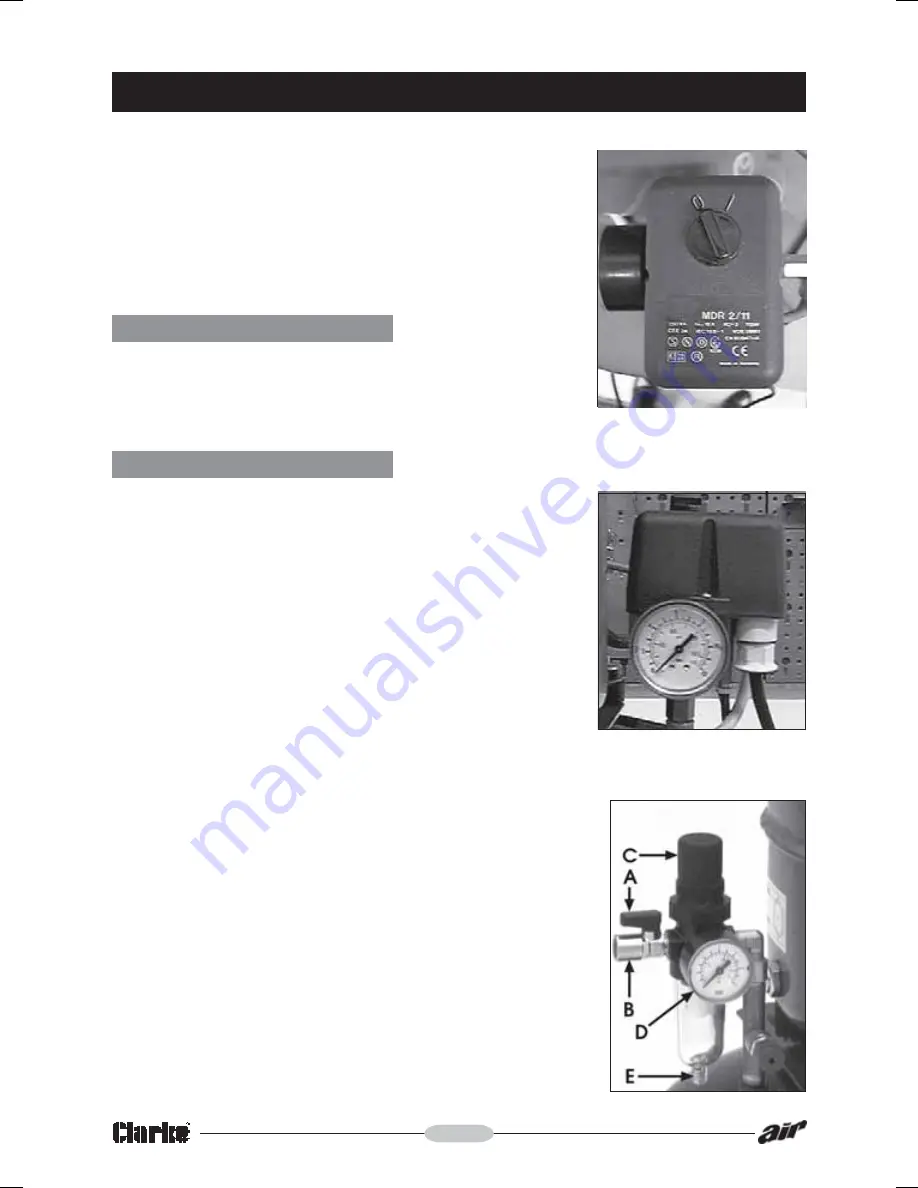

Fig.3

Firstly, ensure the compressor is on level ground...do not allow

it to run if it is standing on an incline.

Check also that the mains voltage corresponds with that

shown on the data label on the side of the compressor.

Ensure that the ON/OFF switch, mounted on the Pressure

Switch (shown in fig. 1), is turned to the ‘0’ (OFF) position,

then plug in and switch ON at the mains supply.

NOTE: SHHH2 ONLY

This model is supplied with a foot switch, which must be

depressed to start the compressor and depressed a second

time to stop it. Ensure the pedal is NOT depressed when

plugging in to the mains supply.

ALL OTHER MODELS

1.

To start the compressor, turn the ON/OFF switch to the

‘I’ (ON) position - the motor should start immediately.

NOTE: Should the motor fail to start immediately, it is possible

that the air receiver is already full of air. Check the tank

pressure gauge (see fig. 2). If you release air, by opening

the air outlet tap, the motor will start automatically once the

cut-in pressure is reached. (This does not apply to the SHHH2)

Before connecting your airline to the compressor,allow

it to run for 10 - 15 seconds, with the air outlet tap,(A, Fig.

3) completely open to permit a good distribution of the

lubricating oil.

2.

Close the outlet tap then connect one end of suitable

air hose to the connector at the filter/regulator outlet,

(B, Fig. 3) and the other end to the equipment to be

used.

3.

Set the outlet pressure by adjusting the Pressure

Regulator.

T

o do this, lift the Pressure Regulator Knob (C Fig. 3),

and turn it clockwise to increase pressure, anticlockwise

to decrease as noted on the Outlet Gauge, (D, Fig. 3).

To lock the Regulator Knob and hence the outlet

pressure, push the Regulator Knob down until it clicks

into place.

NOTE: For most spray work do not exceed 50 psi (unless

following paint manufacturer’s instructions).

For other airline equipment such as, tyre gauges, staple guns,

paraffin guns etc., it may be necessary to set the operating

pressure at a higher (or lower) level.

6