MAINTENANCE

DAILY

1. Check the oil level before you start and top up if necessary - use Clarke

Synthetic Air Compressor Oil ONLY, available from your Clarke dealer...

Part No. 3050795

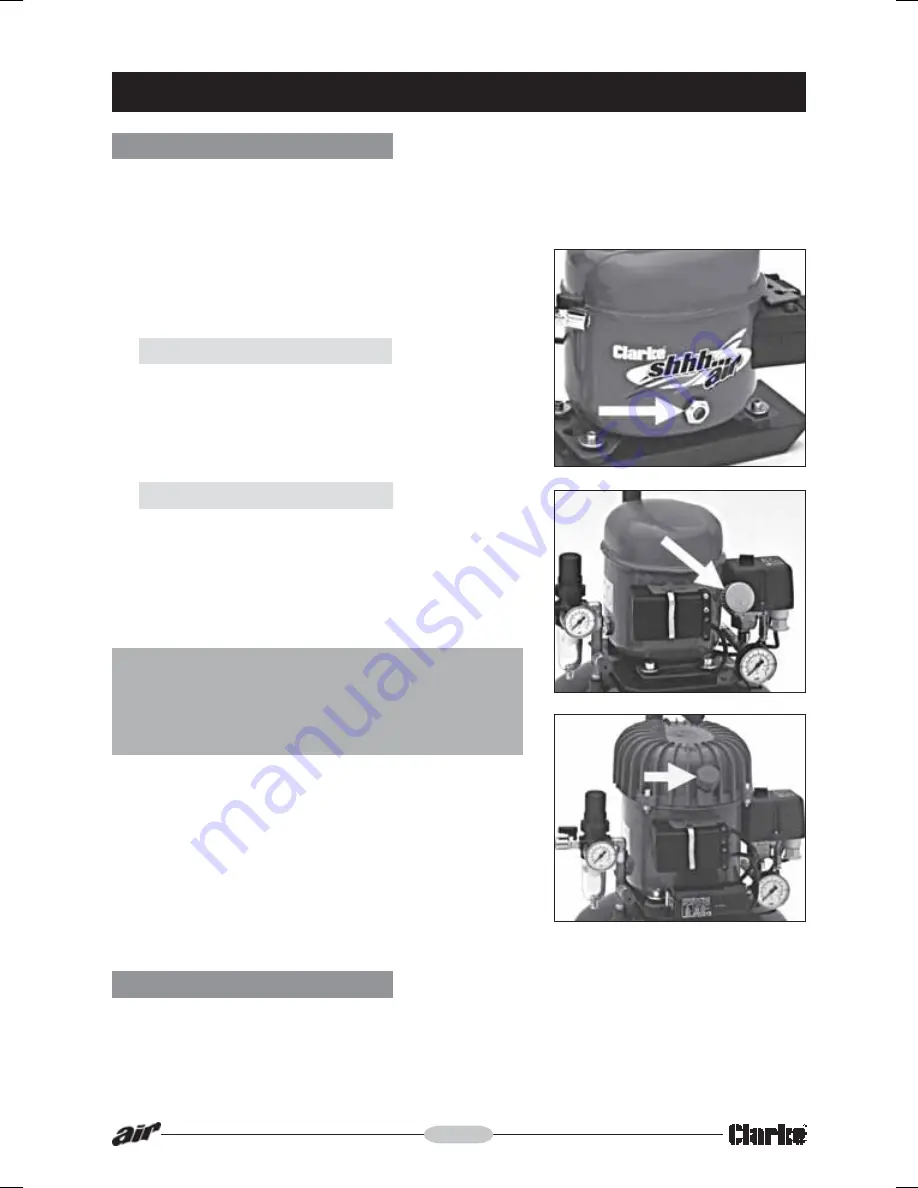

The oil level is checked by viewing the oil

sight glass, shown arrowed in Fig. 5

To add oil, proceed as follows:

A. SHHH 2 and 2/9

Carefully pull off the air filter, shown

arrowed in Fig. 6, and inject oil into the

air breather tube, until the oil level is

midway on the oil sight glass.

B.

SHHH 3/9 and 3/24

Remove the oil filler plug, shown

arrowed in Fig. 7, and top up until the

oil level is midway on the oil sight glass.

Take great care not to cross thread the

filler plug when replacing.

IMPORTANT:

DO NOT replace the oil filler plug with

anything other than the original, as the filler

plug doubles as an air breather

2. Drain any condensate that may have accum-

ulated in the air outlet filter, by pushing the

valve (E Fig. 3), upwards. (Not SHHH 2)

3. When you have finished with the compressor,

ALWAYS

open the drain valve - at the base of

the tank, to expel all air, and to allow any

condensate to drain off. (Not SHHH 2)

DO NOT FORGET to close the valve again when the tank is empty.

PERIODICALLY

1. Renew Oil Filler Plug/Air Breather every 500 hours of operation.

2. If oil becomes contaminated it will be necessary to drain it by removing the

filler plug/air filter, inverting the compressor and allowing time for the oil to

drain, before filling with new SYNTHETIC OIL to the middle of the oil sight glass.

Fig.7

Fig.6

Fig.5

9