4

WATER CONNECTIONS

IMPORTANT

:

DO NOT connect the pump to the power supply until the hose/pipe

installation is completed.

Because of the variety of possible installations, no plumbing accessories are

supplied as standard with your pump. However, accessories designed specifically

for this range of pumps are available from your CLARKE dealer and are listed on

page 6.

from an above ground pool. However, it is possible

to draw water from a sunken pool, providing the

suction lift does not exceed the distance specified

for your pump (see Specifications on page 7).

A. SUCTION LIFT

The suction lift i.e. the vertical distance between

the water level and the pump should not exceed

the distance specified for your pump (see

Specifications on page 7).

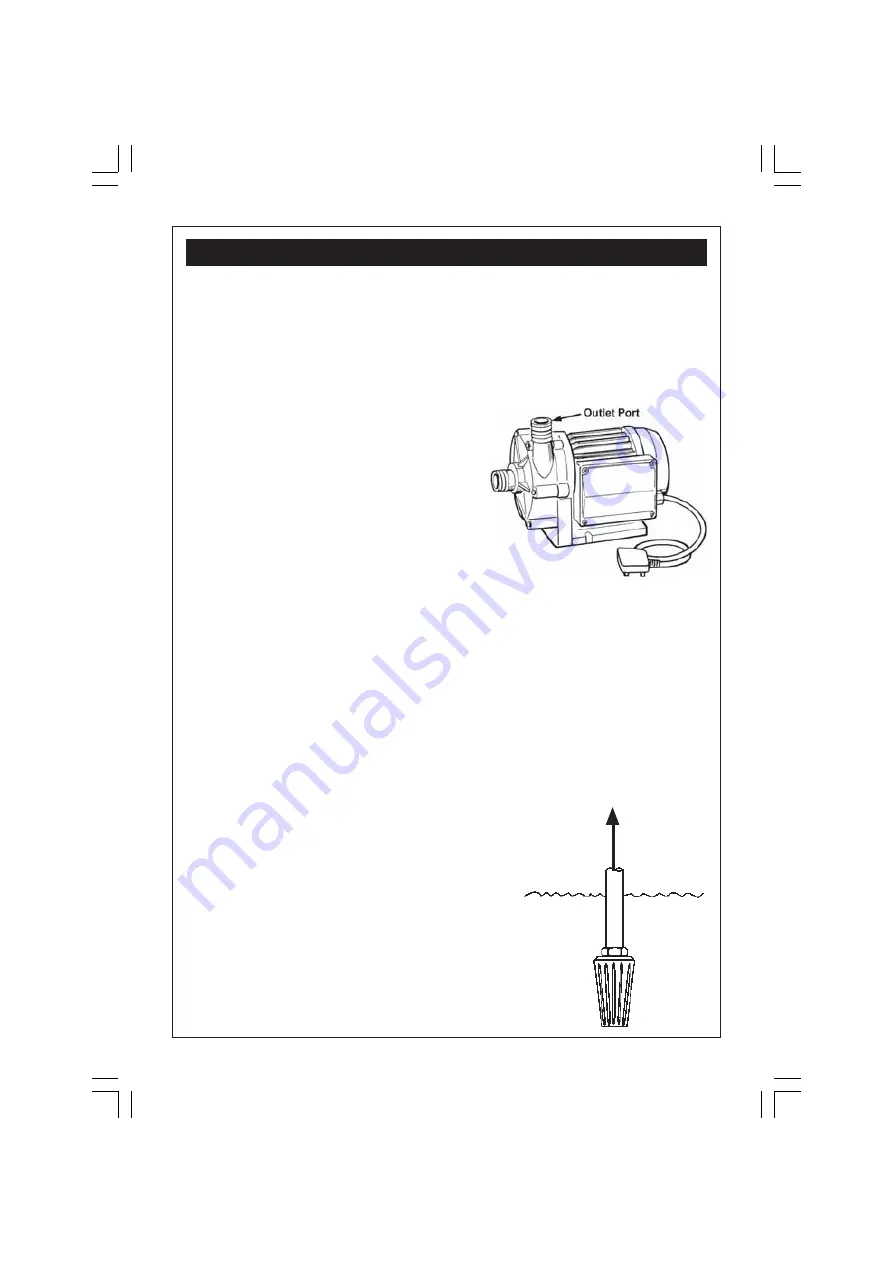

A foot valve/filter MUST be fitted to the lower end

of the suction hose, (as illustrated in fig.2), so as to

help retain water in the suction system.

Remember.... this is NOT a self priming pump.

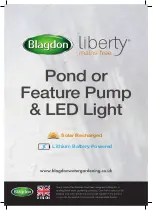

The pump must always be installed and

operated in a horizontal position i.e. with the

outlet port (see Fig.1), facing vertically

upwards. The fixing slots in the base should

be used as necessary to secure the pump

firmly in its operating position. Also, ensure

that there is adequate air circulation around

the motor.

Avoid situations where there is the risk of

water coming into contact with the outside

of the pump. Neither the motor or the

terminal box are intended to be waterproof.

Attach suitable 1” ID hose to the inlet port, securing with a worm drive clip. The

other end of the hose should be connected to a strainer, or foot valve/filter

depending upon the type of installation (see below), and should rest on the bottom

of the pool. Ensure all connections are air tight.

Attach also a suitable 1” ID hose to the outlet port using a worm drive clip. The

other end of the hose should be connected to your Water Filter (available from

your Clarke dealer - see page 6). Ensure there are no kinks in the hose.

These notes are for guidance on how to achieve a proper working system.

The schematic diagrams, figs. 3 and 4, illustrate possible methods of pipework

installation. This pump is designed primarily, to br gravity fed, that is, drawing water

Fig.1

Foot Valve/

Filter

Fig.2