5

The delivery head i.e. the vertical

distance between the pump and

the point of discharge should not

exceed distance specified for your

pump (see Specifications, page

7).

When suction lift is used to draw

water into the pump it is essential

that all connections and hoses are

1.

With the pump, all inlet pipes/hoses and the foot valve in position, slowly pour

water into the outlet port. Wait until all air is expelled...this may take a minute

or two...and fill to the brim before connecting the outlet hose to the outlet

port. The hose is then led away to the water filter.

2.

Switch on the pump. Water should start to flow through the system.

Check for leaks and repair as necessary

Do not allow the pump to run dry, otherwise the seal between the pump and motor

may be damaged. If a leak is noticed at this point it may indicate that the seal is

worn and therefore in need of replacement. Contact your CLARKE dealer, or the

Clarke International Service Department for advice.

B

GRAVITY FEED

Do not place any restriction on the

inlet side of the pump.

The delivery head i.e. the vertical

distance between the pump outlet

and the point of discharge should

not exceed distance specified for

your pump (see Specifications, page 7).

To prevent unnecessary strain or possible distortion to the pump, ensure that

adequate support is provided to the hoses and/or pipes. Remember they will be

considerably heavier when filled with water.

Remember - this pump is designed for pumping CLEAN WATER with small solids in

suspension, ONLY. DO NOT USE for pumping chemicals or other corrosive liquids

(other than pool purification chemicals in their correct mix ratio).

Protect the pump and pipework from

freezing.

The formation of ice may cause

serious damage.

NOTE: For the fitting of filters/strainers, please consult the manufacturers manual.

completely air tight, otherwise the system will

not work.

Before pumping will start it is essential to

completely fill the suction side with water. This

is known as

priming the pump

and is carried

out as follows :-

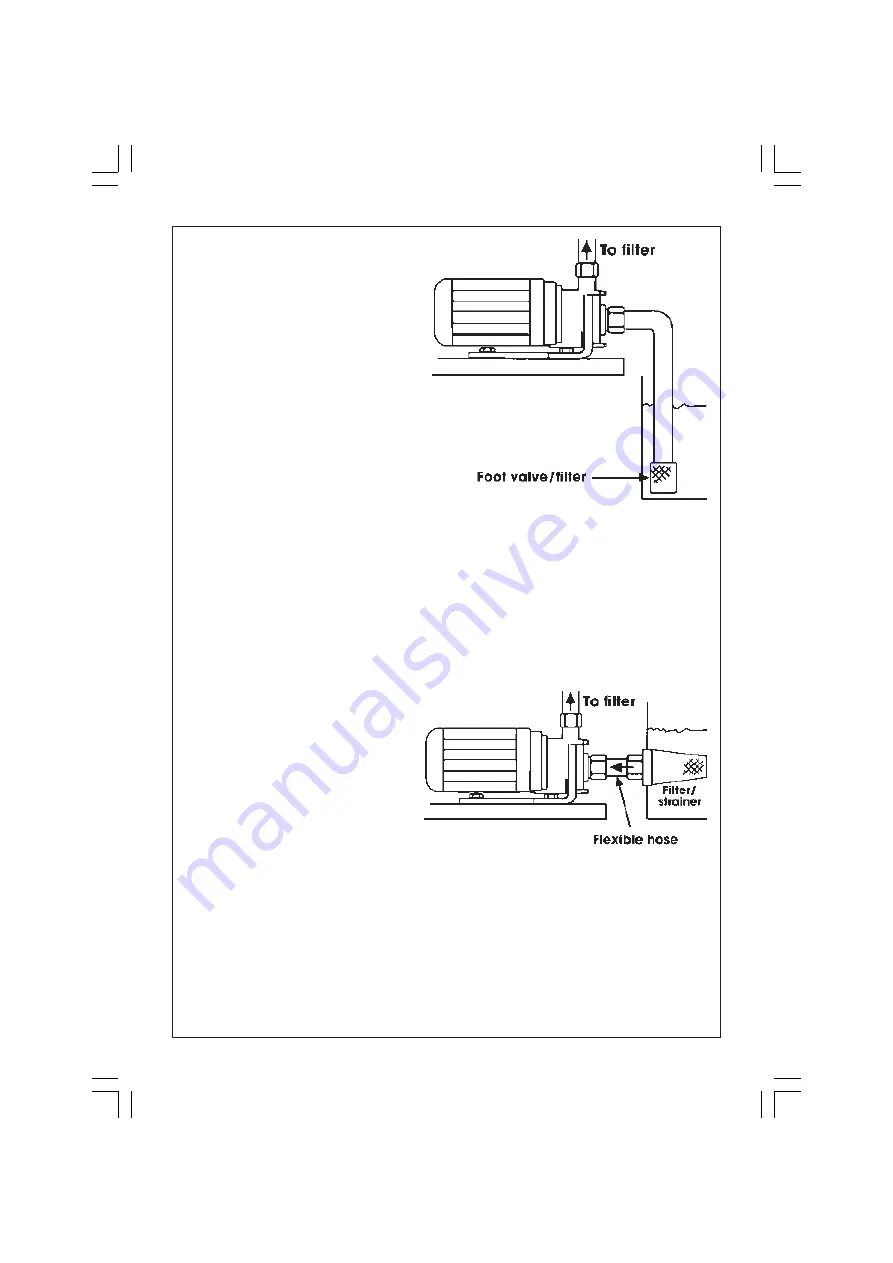

Fig.4

Fig.3