SAFETY PRECAUTIONS

1.

ALWAYS

inspect the jack before use. Ensure that all parts are in good condition and

operating smoothly, the wheels are sound and that no cracks or distortion is apparent.

If in doubt

do not use

. Have the parts replaced or consult your CLARKE dealer.

2.

ALWAYS

ensure the jack is on a firm solid base, and that there is no likelihood of it slipping

when under load.

3.

ALWAYS

ensure the load is taken by the

FULL

saddle and that the point of lift on the load,

is of sufficient strength to support the full load adequately.

4.

ALWAYS

ensure that the load is stabilised or supported in such a way that it will not shift

during lifting or lowering operations.

5.

ALWAYS

use supports to stabilise the load once lifted.

NEVER

work on or under a load unless it

is fully and adequately supported.

NEVER

rely upon the jack to hold the load in position.

6.

ALWAYS

ensure that all personnel are well clear of a load being raised, or lowered.

7.

NEVER

push a load off the jack.

8.

NEVER

exceed the rated load for the jack (see ‘Specifications’).

9.

NEVER

use if an oil leak is apparent...Consult your Clarke dealer.

10.

NEVER

attempt to disassemble the jack. Consult you CLARKE dealer if problems arise

11.

NEVER

move a load using the jack as a dolly. This jack is for lifting ONLY..

ASSEMBLY

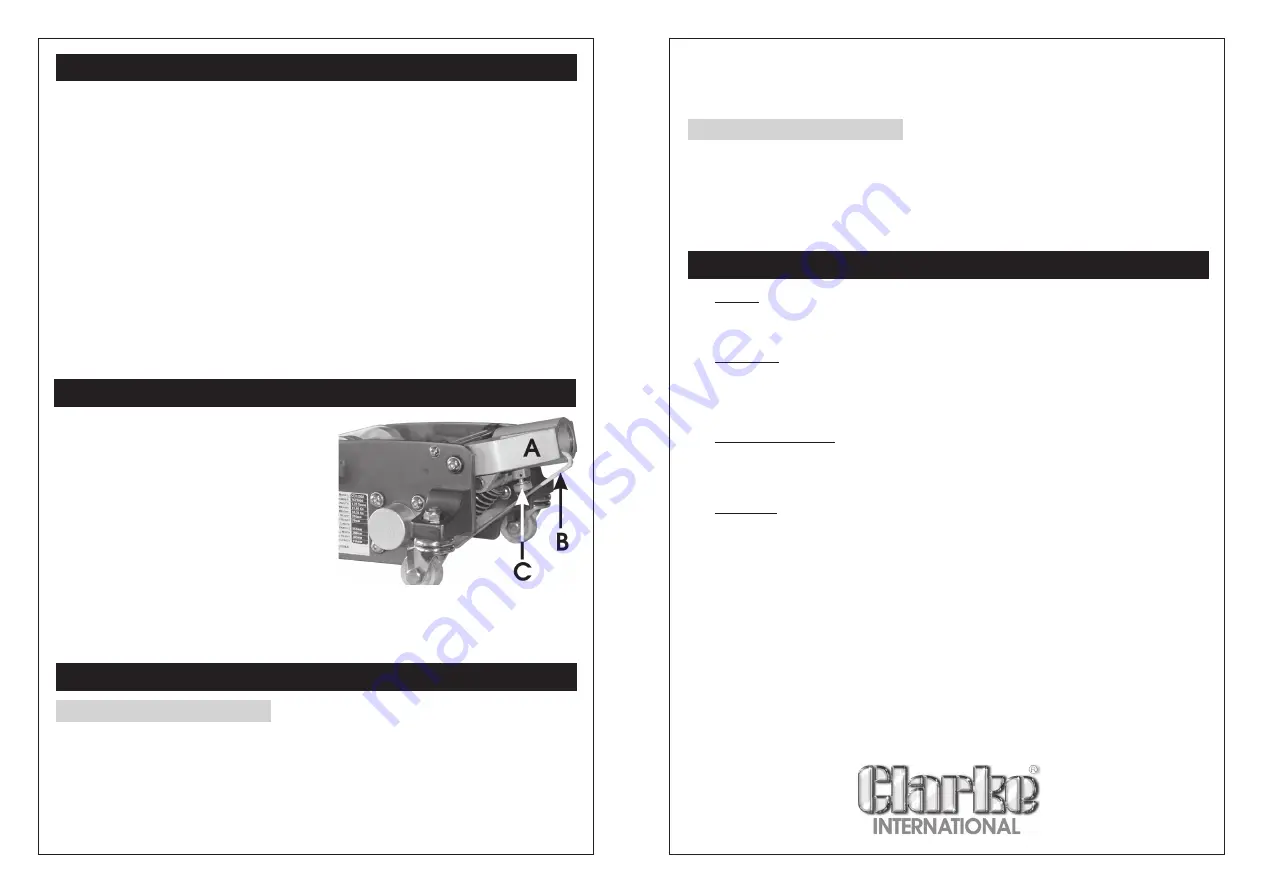

For transit and packaging purposes, you will

note that the Arm - ‘A’ in illustration opposite,

is held down by a retaining wire, shown at ‘B’.

To remove the wire, press down on the Arm

sufficiently for the wire to be removed.

Carefully allow the Arm to reassert.

Attach the two halves of the handle, ensuring

the spring pin in the top half, locates correctly

in the hole in the bottom half .

Insert the end of the handle into the Arm so

that the square hole in the handle engages

with the square shaft in the Arm, (it may be necessary to unscrew the setscrew - shown

at ‘C’, in order to do so).

With the handle firmly in place, screw in the setscrew so that it is finger tight, then unscrew

by one half a turn....the handle should rotate smoothly.

OPERATION

RAISING A LOAD

Ensure the load is chocked and stable and on firm level ground, before manoeuvring the

jack so that the saddle is directly beneath the lifting point. Consult the vehicle handbook to

determine the correct lifting points.

Turn the handle, fully clockwise and pump the handle to raise the saddle, As it meets the

lifting point, check to ensure it is in full contact and there is no obstacle to prevent a clean

lift, before proceeding to pump the handle further to raise the load. UNDER NO

CIRCUMSTANCES attempt to move the load whilst supported by the jack.

Place axle stands or suitable supports beneath the vehicle, before VERY GENTLY turning the

handle anticlockwise. This action will open the release valve to lower the load on to the

stands. DO NOT jerk the handle...ensure it lowers under complete control on to the axle

stands which must be correctly positioned and take the weight evenly.

LOWERING A LOAD

First jack up the load in order to clear the axle stands or supports, then, when the supports

have been removed, check to ensure that there are no obstacles that could prevent the

load from lowering without hindrance, and that all personnel are well away from the site.

VERY GENTLY turn the handle anticlockwise and the load will lower. DO NOT jerk the

handle....lower the load under complete control....DO NOT allow it to lower too quickly as

this could damage the pump seals

MAINTENANCE

Daily

.

Inspect for distortion of components, and security of all nuts and bolts. If in doubt, do not use.

Have damaged parts repaired or replaced. If necessary, consult your CLARKE dealer.

Monthly

Oil all joints, linkages, and front roller hubs with machine oil.

NOTE: Lubrication and cleanliness is important as dirt, rust etc. can cause a jerky action

which could damage internal components.

Every 6 months

Carry out a thorough inspection for serviceability of components and check for oil leaks.

Only a very

slight

oil seepage is permissible. If a leak is evident, take the jack out of service,

and consult your CLARKE dealer.

Storage

Store in a dry place where it cannot be attacked by the elements with the ram in its fully

retracted position. If stored for long periods, inspect at least twice a year, clean and re-oil.

For servicing, contact your CLARKE dealer, or CLARKE International Service Dept..

There are no user serviceable parts within this equipment except for those listed overleaf.

Should the Jack not operate properly, consult your Clarke Dealer, or Clarke Service

department on 020 988 7400.