10

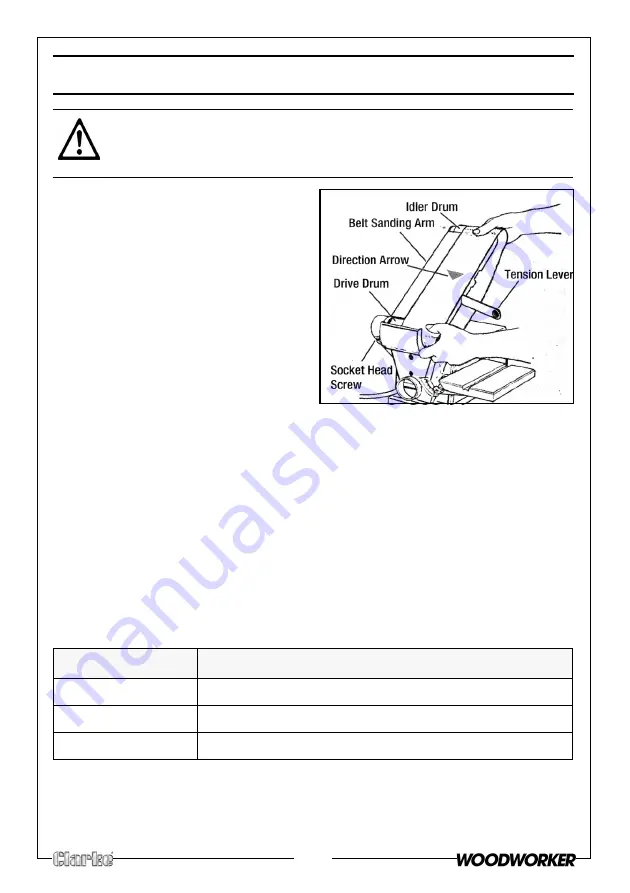

CHANGING THE SANDING BELTS

1. Loosen the socket head screw

using the 6 mm hex wrench

provided.

2. Raise the belt sanding arm as

shown.

3. Slide out one end of the tension

lever as shown to release belt

tension.

4. Remove the tray located on the

bottom of the belt sanding arm by

loosening the two screws on the

back of the belt sanding arm.

5. Slide the sanding belt off of the drive and idler drums.

6. Slide new sanding belt over the drive and idler drums. Ensure the belt is

centred on both drums and is the right way round.

7. Return the tension lever into its original positiom to apply tension to the belt.

8. Replace the tray and tighten the two screws on the back of the belt

sanding arm.

9. Lower the belt sanding arm and tighten the socket head screw using the

6mm hex wrench provided.

CONSUMABLES

Sanding Belts are available from your Clarke dealer.

10. Before using, check belt tracking as described in the next section and

adjust as necessary.

CAUTION: CHECK THE INSIDE OF THE BELT FOR A "DIRECTION ARROW". IF

PRESENT, INSTALL THE BELT WITH THE ARROW POINTING IN THE SAME

DIRECTION AS THE DIRECTION INDICATOR ON THE HOUSING.

Grit

Part number

Fine

6502096

Medium

6500808

Course

6502101