Page 21 of 41

Note:

Per NFPA 25 standards, the fuel tank level

must never be less than 67% of its capacity.

Maximum Allowable Fuel Head above Fuel pump,

Supply or Return.

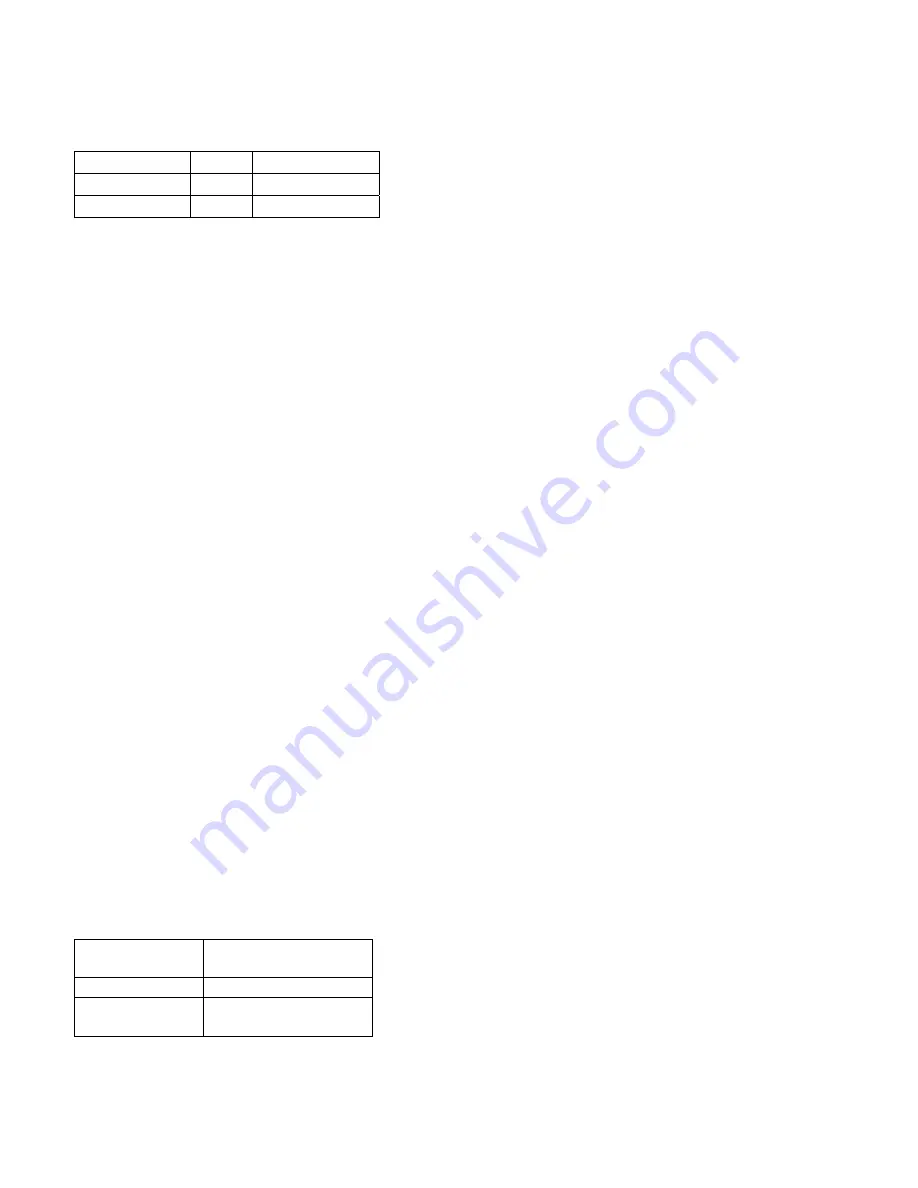

Engine model

feet

meters

ZE4H 6.5 2.0

ZF6H 6.5 2.0

3.1.5

Fuel Injection Pump Components

Run-Stop Solenoid (external to Injection Pump) part

numbers consult factory.

3.2

AIR/EXHAUST SYSTEM

3.2.1

Ambient Conditions

Clarke engines are tested in accordance with SAE

J1349 (Clarke USA) or ISO 3046 (Clarke UK). In

this capacity they may be derated to meet certain site

conditions, failure to do so can seriously impede the

performance of the engine and could lead to

premature failure.

3.2.2

Ventilation

The engine must be provided with adequate

ventilation to satisfy the requirements of the

combustion system, radiator cooling systems where

fitted, and allow adequate dissipation of radiated heat

and crankcase emissions. For all this data refer to

Installation & Operation Data (see Page 5). This data

can be used for proper sizing of inlet and outlet

louvers.

3.2.3

Standard Air Cleaner

The standard air cleaner is a reusable type. Should a

situation occur where the air cleaner becomes

plugged with dirt (starving the engine of air), loss of

power and heavy black smoke will result; if equipped

air filter restriction indicator (ref. Fig. #17A); the air

cleaner should be serviced immediately. See

Figure

#39

for air cleaner part numbers by Clarke Engine

Model.

Base engine

Air filter restriction

(inches of water)

ZE4H-UFAD60 25

ZF6H-UFAA60

ZF6H-UFAC70

25

CAUTION:

Do not attempt to remove the air

cleaner while an engine is running nor run the engine

while the air cleaner is off. Exposed components

could cause severe injury to personnel and major

internal engine damage could occur should any

foreign matter be drawn into the engine.

The air cleaner manufacturer recommends the

following:

1.

The pre-oiled reusable elements are serviced

with a special oil. The elements can be

serviced or replaced.

2.

Figure#15

shows the air filter service

instructions.

3.

When servicing the element is not practical,

you can improve filter efficiency by re-

spraying with oil.

NOTE:

Do not attempt this while engine is running

NOTE:

Do not over oil the reusable element