Page 24 of 41

When the engine has cooled, check the oil

level on the dipstick and put more oil into the

sump, if necessary.

9)

Return the unit back into service by returning

the main pump controller selector to

“automatic” position and the manual

operating lever to AUTO-OFF position.

3.3.4 Oil Specification

This engine is factory-filled with oil.

Important: Do not add makeup oil until the oil

level is BELOW the add mark on the dispstick.

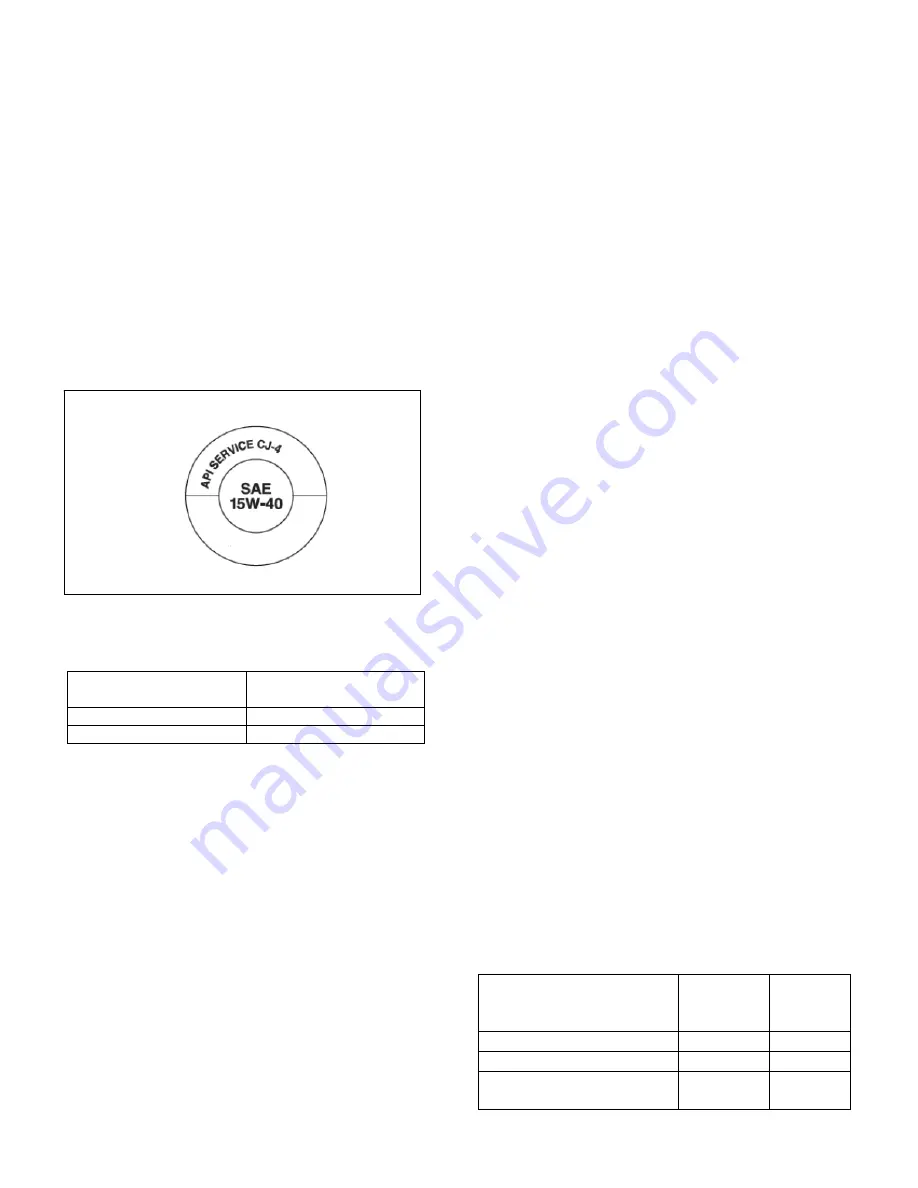

Oil spec to be used for all engine models:

API Symbol:

Note: CF-4, CG-4, CH-4 and CI-4 are also acceptable

Figure #20

3.3.5

Oil Capacities (Including Filter)

ENGINE

MODEL

OIL CAPACITY

QUARTS (LITERS)

ZE4H – All Models

12.2 (11.5)

ZF6H – All Models

22.7 (21.5)

Figure #21

3.4 COOLING SYSTEM

3.4.1 Intended Engine Operating Temperature

The ZF6H engines are provided with either a heat

exchanger or radiator to maintain the engine coolant

temperature within recommended operating

guidelines.

The ZF6H engines have an intended engine operating

temperature of 160º F (71ºC) to 190º F (88º C). A

high coolant temperature switch is provided to

indicate a high coolant temperature alarm at 205º F

(96º C).

3.4.2 Engine Coolant

The following information is provided as a guide for

Clarke Engine users in the selection of a suitable

coolant.

The water/ethylene glycol/inhibitor coolant mixture

used in Clarke engines must meet the following basic

requirements:

Provide for adequate heat transfer.

Provide protection from cavitation damage.

Provide a corrosion/erosion-resistant

environment within the cooling system.

Prevent formation of scale or sludge deposits

in the cooling system.

Be compatible with engine hose and seal

materials.

Provide adequate freeze and boil over

protection.

WARNING

A water and anti-freeze solution is required for

pump installations. Premixing this solution prior

to installing is required. This prevents possible

pure anti-freeze chemical reactions to block

heater elements which can burnout the element.

Please see the I&O section (see Page 5) for proper

cooling system capacities of each model.

3.4.3 Water

Water can produce a corrosive environment in the

cooling system, and the mineral content may permit

scale deposits to form on internal cooling surfaces.

Therefore, inhibitors must be added to control

corrosion, cavitation, and scale deposits.

Chlorides, sulfates, magnesium and calcium are

among the materials which make up dissolved solids

that may cause scale deposits, sludge deposits,

corrosion or a combination of these. Chlorides

and/or sulfates tend to accelerate corrosion, while

hardness (percentage of magnesium and calcium salts

broadly classified as carbonates) causes deposits of

scale. Water within the limits specified in

Figure

#22 is satisfactory with an engine coolant when

properly inhibited. Use of deionized or red distilled

water is preferred.

Materials

Parts per

Million

Grains

per

Gallon

Chloride (Max.)

40

2.5

Sulfates (Max.)

100

5.8

Total Dissolves Solids

(Max.)

340

20