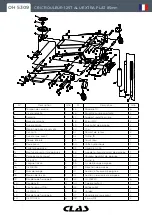

OH 5309

EXTRA FLAT ALUMINUM TROLLEY JACK 1.25T 85mm

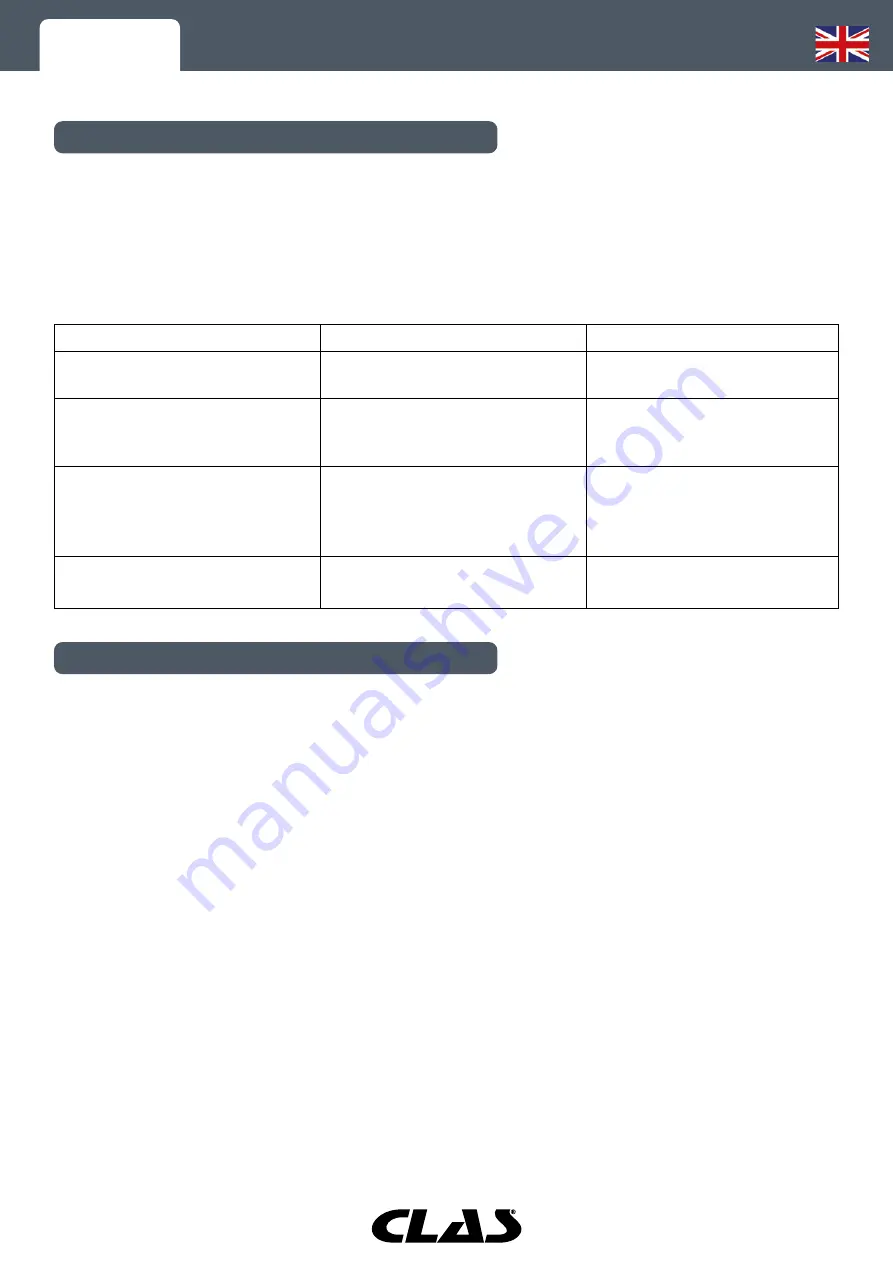

TROUBLES

System air purge

1 - Turn release valve counter clock wise one full turn to open.

2 - Pump handle eight full strokes.

3 - Turn release valve clock wise to close valve.

Problem

Causes possibles

Solution

Jack will not lift to full

height

Low oil level

Check oil level

Jack will not hold load

Release valve not closing

Oil contaminated

Pump valves not sealing

Call your reseller

Lift arm will not lower

Parts worn

Internal damage

Broken return spring or

unhooked

Call your reseller

Jacks feel spongy when

lifting

See system air purge

section

See system air purge

section

SPARE PARTS

Also sold in retail:

SA 5411 : Pair of front wheels

SA 5412 : Pair of rear wheels

SA 5413 : Rubber pad

SA 5414 : Joints repair kit

SA 5415 : Replacement CV joints

Summary of Contents for OH 5309

Page 12: ...OH 5309 EXTRA FLAT ALUMINUM TROLLEY JACK 1 25T 85mm...

Page 13: ......

Page 14: ......

Page 15: ......