20

6.4 Installation for the first time

Air and moisture in the refrigerant system have

undesirable effects as below:

●

Pressure in the system rises.

●

Operating current rises.

●

Cooling or heating efficiency drops.

●

Moisture in the refrigerant circuit may

freeze and block capillary tubing.

●

Water may lead to corrosion of parts in the

refrigerant system.

Therefore, the indoor units and the pipes

between indoor and outdoor units must be leak

tested and evacuated to remove gas and

moisture from the system.

Gas leak check (Soap water method):

Apply soap water or a liquid neutral

detergent on the indoor unit connections or

outdoor unit connections by a soft brush to

check for leakage of the connecting points of

the piping. If bubbles come out, the pipes have

leakage.

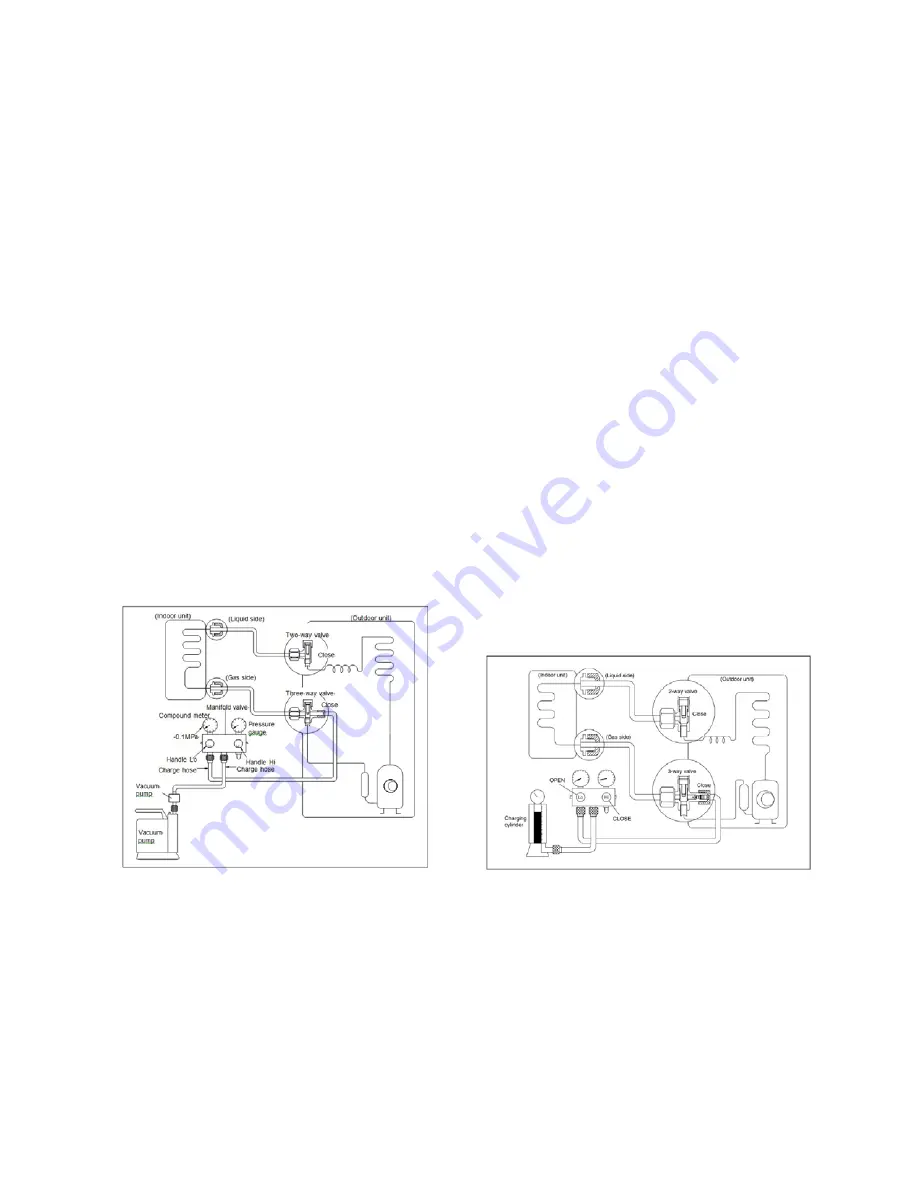

1. Air purging with vacuum pump

1) Completely tighten the flare nuts of the

indoor and outdoor units, confirm that both

the 2-way and 3-way valves are set to the

closed position.

2) Connect the charge hose with the push pin

of handle lo to the 3-way valves gas service

port..

3) Connect the charge hose of handle hi

connection to the vacuum pump.

4) Fully open the handle Lo of the manifold

valve.

5) Operate the vacuum pump to evacuate.

6) Make evacuation for 30 minutes and check

whether the compound meter indicates

-0.1Mpa(14.5Psi)

. If the meter does not

indicate

-0.1Mpa(14.5Psi)

after pumping 30

minutes, it should be pumped 20 minutes

more. If the pressure can’t achieve

-0.1Mpa(14.5Psi

) after pumping 50 minutes,

please check if there are some leakage

points. Fully close the handle Lo valve of the

manifold valve and stop the operation of the

vacuum pump. Confirm that the gauge

needle does not move (approximately 5

minutes after turning off the vacuum pump).

7) Turn the flare nut of the 3-way valves about

45° counterclockwise for 6 or 7seconds

after the gas coming out, then tighten the

flare nut again. Make sure the pressure

display in the pressure indicator is a little

higher than the atmosphere pressure. Then

remove the charge hose from the 3 way

valve.

8) Fully open the 2 way valve and 3 way valve

and securely tighten the cap of the 3 way

valve.

2. Air purging by refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way

valves are set to the closed position.

2). Connect the charge set and a charging

cylinder to the service port of the 3-way valve.

3). Air purging.

Open the valves on the charging cylinder and

the charge set. Purge the air by loosening the

flare nut on the 2-way valve approximately 45’

for 3 seconds then closing it for 1 minute; repeat

Summary of Contents for MROHC09AS

Page 14: ...12 5 Wiring Diagram 5 1 Indoor Unit MWOHC09S MWOHC12S MWOHC18S ...

Page 15: ...13 MWOHC24S ...

Page 16: ...14 5 2 Outdoor Unit MROHC09AS MROHC12AS ...

Page 17: ...15 MROHC18AS ...

Page 18: ...16 MROHC24AS MROHC09AS MROHC12AS ...

Page 19: ...17 MROHC18AS ...

Page 29: ...27 T2 7 C 44 6 F the compressor frequency will not be limited ...

Page 53: ...51 Take the 9k model as example P V P U ...

Page 54: ...52 N U P W ...

Page 55: ...53 N W N V ...