15

Wood Heat Utilization

The top down method of fire building is recommended for this appliance. After making sure that the stove air

intake controls are fully open (open all three air controls to there maximum setting). Place the largest pieces of

wood on the bottom, laid in parallel and close together. Smaller pieces are placed in a second layer, crossways

to the first. A third layer of still smaller pieces is laid crossways to the second, this time with some spaces between.

Then a fourth layer of loose, small kindling and twisted newspaper sheets tops off the pile.

Higher efficiencies and lower emissions generally result when burning air dried seasoned hardwoods, as

compared to softwoods or to green or freshly cut hardwoods.

DO NOT BURN:

1. Garbage;

2. Lawn clippings or yard waste;

3. Materials containing rubber, including tires;

4. Materials containing plastic;

5. Waste petroleum products, paints or paint

thinners, or asphalt products;

6. Materials containing asbestos;

7. Construction or demolition debris;

8. Railroad ties or pressure-treated wood;

9.

Manure or animal remains;

10. Salt water driftwood or other previously salt water

saturated materials;

11. Unseasoned wood; or

12. Paper products, cardboard, plywood, or

particleboard. The prohibition against burning

these materials does not prohibit the use of fire

starters made from paper, cardboard, saw dust,

wax and similar substances for the purpose of

starting a fire in an affected wood heater.

Burning these materials may result in release of toxic fumes or render the heater ineffective and cause smoke.

Dead wood lying on the forest floor should be considered wet, and requires full seasoning time. Standing dead

wood can usually be considered to be about 2/3 seasoned. Splitting and stacking wood before it is stored

accelerates drying time. Storing wood on an elevated surface from the ground and under a cover or covered

area from rain or snow also accelerates drying time. A good indicator if wood is ready to burn is to check the

piece ends. If there are cracks radiating in all directions from the center then the wood should be dry enough

to burn. If your wood sizzles in the fire, even though the surface is dry, it may not be fully cured, and should be

seasoned longer.

Do not burn manufactured logs made of wax impregnated sawdust or logs with any chemical

additives. Manufactured logs made of 100% compressed sawdust can be burned, but be

careful burning too much of these logs at the same time. Start with one manufactured log and

see how the stove reacts. You can increase the number of logs burned at a time to making

sure the temperature never rises higher than 475 °F (246 °C) on a magnetic thermometer for

installation on single wall stove pipes or 900 °F (482 °C) on a probe thermometer for installation

on double wall stove pipe.

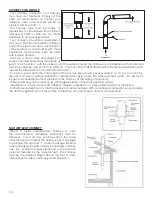

The thermometer should be

placed about 18” (457 mm)

above the stove. Higher

temperatures can lead to

overheat and damage your

stove.

Your furnace was designed

to burn wood only; no other

materials should be burned.

Waste and other flammable

materials should not be

burned in your furnace. DO

NOT USE CHEMICALS OR

FLUIDS TO START THE FIRE.

DO NOT BURN GARBAGE,

GASOLINE,

NAPTHA,

ENGINE OIL, OR OTHER

INAPPROPRIATE MATERIALS.

Any type of wood may be

used in your furnace, but

specific varieties have better

energy yields than others.

Please consult the following

table in order to make the

best possible choice.

TYPE

WEIGHT

(LBS. CU. FT., DRY)

PER CORD

EFFICIENCY

RANKING

SPLITS

MILLIONS BTU’s/

CORD

Hickory

63

4500

1.0

Well

31.5

White Oak

48

4100

.9

Fair

28.6

Red Oak

46

3900

.8

Fair

27.4

Beech

45

3800

.7

Hard

26.8

Sugar Maple

44

3700

.6

Fair

26.2

Black Oak

43

3700

.6

Fair

25.6

Ash

42

3600

.5

Well

25.0

Yellow Birch

40

3400

.4

Hard

23.8

Red Maple

38

3200

.3

Fair

22.6

Paper Birch

37

3100

.3

Easy

22.1

Elm/

Sycamore

34

2900

.2

Very

Difficult

20.1

Red Spruce

29

1800

.1

Easy

16.1